Independent routing of one or more packages on individual carriers through a transport system is possible with MCS. Some packages can be treated on a custom basis, while others follow a prescribed route, making the system able to accommodate both standard and custom products on a single line.

Each transport carrier in the MCS can move freely and independently from all other carriers. Carriers can be moved towards each other without the risk of collision and are easy to position. Also, several carriers can be grouped together and moved synchronously at fixed distances.

Linear motors drive and position the transport carriers. Propulsion for each individual carrier in the MCS is magnetic. When energized, the electric wingdings of the motor (stator) generate a moving magnetic field. The carriers (the motor’s rotor) with their permanent magnets are pulled along with the liner movement of the magnetic field. In this process, there is a direct relationship between current intensity, magnetic field and the feed force generated.

The MCS complements classic transport solutions, so other transport routes remain unaffected and can accommodate carriers using a low-cost classic transport system or conveyor. Multi-carrier units use transfer-free linkages to existing conveying systems. The MCS offers machine builders entirely new dimensions of flexibility thanks to its modular construction and ease of implementation.

The integrated control concept allows control of both transport motions and motion-control functionality, as well as the coordination of other machine modules. The demonstration unit at PACK EXPO 2015 simulated a packing system.

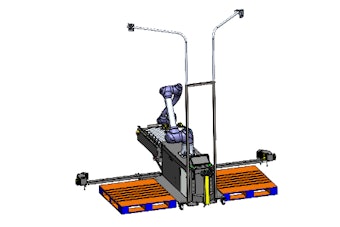

The simple, modular basic mechanical system, which consists of linear motors, a base for the package to be carried on, and a roller conveyor, permits customer-specific configurations to be created and precisely matched to individual applications. The Siemens controller provides full integration of the control and motion control functions for the overall conveying system. In addition to the motion control of the transport system, the Siemens controller can also coordinate motion with other servo-driven machine modules such as fillers or cartoners. This considerably reduces the number of interfaces required and allows flexible integration of the complete system by the OEM.

The MCS incorporates options that are relevant to Industry 4.0. These include the flexible electromechanical design for economic production down to batch sizes of one and decentralized sensors and intelligence incorporated within the work piece carriers and drives. The modular servo controller and the motion controller also fully reflect the cyber-physical integration of Industry 4.0 systems. The simulation function is fully prepared for future system optimization and dimensioning, and program data can be generated from the simulation. The Open Platform Communications United Architecture (OPC-UA) interface enables open integration into Industry 4.0 host environments.

Siemens technology in detail

Flexible system integration: Mechanic and electric

- Operation of the multi-carrier system and further electric axes in a SINAMICS S120 axis group

- Use of all technological degrees of freedom of a SIMOTION (e.g. upwards and downwards synchronization on cam disks)

Multi-dimensional software architecture for efficient commissioning

- Free programming option based on the SIMOTION SCOUT engineering system (user-specific program section, simplification through standard application for Multi-Carrier-System with “zone concept“, mapping of a carrier on a virtual axis)

- Convenient integration of the basic system functionalities via an Open Architecture library (implementation of all segment transitions, switchover of the control modes closed loop - open loop, minimum collision detection)

Efficient implementation of the machine application using the project generator easyProject.