Quick hits:

- With the growing push for sustainability, U.S. consumers might be ready for a trayless ground meat package.

- As consumers put more emphasis on health, demanding more natural, fresh foods, interest is growing in high pressure processing (HPP). Innovations improve the efficiency for both bulk bags and single-serve plastic containers.

- Another innovation is focused on improving efficiency and reducing product waste while cutting and dispensing cut product into totes.

- Read the full food machinery section of the PACK EXPO Innovations Report

- PACK EXPO Video: See how Unibloc-Pump’s swing-arm design makes cleaning easier

| Read the transcript below: |

Hi, I'm Melissa Griffen, contributing editor for ProFood World.

This past fall, more than a dozen editors at PMMI Media Group hit the show floor running at PACK EXPO Las Vegas. That all comes together in the January issue of Packaging World, sister magazine to ProFood World, where we weave together all of the coverage into a single cohesive tapestry called the PACK EXPO Innovations Report.

If you have the chance, the full 100-page report is worth a read. But we’ve also broken it down into more digestible chunks, a part of which covers machinery for the food industry.

First is a trayless ground meat package that Harpak-Ulma had on display at its booth. It’s a package format that hasn’t been seen much yet in the United States but has become increasingly popular in Europe. By eliminating the tray, not only are you removing a whole piece of the packaging, but you also eliminate the trucks and the fuel they would consume to deliver the trays.

The trayless packages are backflushed with a mix of oxygen and carbon dioxide and wrapped on a flow wrapper. European meat companies have not been inserting a soaker pad, only paper. Testing in the U.S. has been done both with and without a soaker pad. The jury is still out on whether it’s needed.

At least historically, U.S. consumers have been pretty set on getting their ground meat in a tray with film overwrap. But given the more recent push for sustainability, this format may replace the old method.

Next, as consumers put more emphasis on health, demanding more natural, fresh foods, interest is growing in high pressure processing (HPP) and what it can do to extend the refrigerated shelf lives of natural products. At PACK EXPO Las Vegas, JBT Avure introduced its FlexiBulk system, which is aimed at optimizing efficiency and throughput significantly.

A drawback to HPP—which extends shelf life of packaged products by using high pressure to inactivate bacteria—is the limitation it puts on the type of packaging that can be used and also the efficiency of the system. Historically, primary containers filled with product are placed into a large basket. The baskets are filled with water and are then put into a pressurizing chamber. Primarily plastic packaging is suitable for this process because things like glass or metal cannot stand up to the intense pressure—up to 87,000 psi—involved in the process.

In recent years, innovative bulk HPP systems have helped broaden the range of packaging materials used. Rather than putting filled primary containers into the HPP basket, a flexible film bag goes into the basket to be pressurized instead. The product from the bulk container can later be put into a wider range of primary containers.

The downside to this bulk HPP approach is that it’s sequential. Only when all three critical processing steps—filling the bulk bag, pressurizing the bulk bag, and emptying the bulk bag’s contents into a tank—are completed can the next batch of product be filled into a bag and a new cycle begin. And that’s where FlexiBulk comes in. Rather than relying on one HPP basket that must be filled, processed, and emptied before the next batch can begin, FlexiBulk deploys multiple HPP baskets, greatly improving throughput efficiency. Also important is that the FlexiBulk baskets accept either bulk bags or single-serve plastic containers simultaneously.

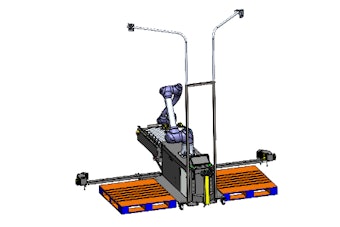

The last piece of equipment focuses in on improving efficiency while also reducing product waste. The Urschel TranSlicer (ETRS) cutter features a built-in discharge conveyor, which facilitates the dispensing of cut product into totes. The built-in conveyor also assists with the effective capture of slivered, small cuts of leeks, onions, or peppers to promote complete discharge from the machine.

Hinged/sliding panels offer full access to all key areas of the machine to simplify maintenance and washdowns, while sloped surfaces throughout the machine, including a self-draining frame, make cleaning easier. Engineered for elongated food products, the belt-fed unit employs different styles of 20-inch diameter cutting wheels to create flat or crinkle slices and julienne cuts.

Thanks and see you next time on Take Five with ProFood World.