This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Zero-Max, a provider of motion control systems and a coupling manufacturer, announces that its ServoClass Couplings are designed to provide reliability and misalignment advantages in servo motor and stepper motor driven applications.

Demanding applications require a coupling that holds up to shock loads caused by rapid acceleration and deceleration, start/stop conditions, and torque reversals in these servo driven systems, which the company believes it has achieved with its ServoClass Couplings. According to Zero-Max testing and field experience, the products provide the durability and reliability necessary for longer life and increased machine uptime in these applications compared to other coupling styles.

“Misalignment between shafts on equipment exists in the form of angular, parallel (radial), and axial misalignment,” says a Zero-Max spokesperson. “No matter how careful two shafts are aligned, they are never ‘perfectly’ aligned. Additional misalignment can also creep in over time from deflection due to torque loads and forces on the machine, machine wear, and eventual settling of the machine base. The ServoClass Coupling, within its ratings, handles these types of misalignments readily and easily.”

The company reports that the ServoClass Coupling is designed to have a misalignment advantage over bellows couplings which should provide for a longer lifetime where the misalignment exists. The reason for this is that the ServoClass Coupling is meant to not be as radially stiff as a bellows coupling which should reduce the reaction loads on the connected components and stresses within the coupling itself. The ServoClass Coupling is designed to handle torque, rotation, and misalignment simultaneously, which would then provide longer life.

The ServoClass Couplings are also supposed to be an improvement on Jaw/spider couplings during demanding applications. This is due to the product being made to not deteriorate as quickly from heat and fatigue. Also, jaw/spider couplings experience torsional windup in higher torque applications and have longer settling times when stopping higher inertial loads, says the company. This results in increased cycle times and reduced machine throughput. The ServoClass Coupling’s misalignment capacity and high torsional stiffness are meant to apply to these issues.

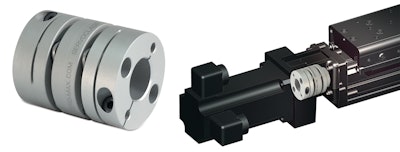

The Zero-Max ServoClass Couplings are made to have a sleek, compact, and robust design that performs more reliably in 24/7 servo motor applications. The ServoClass Coupling also have their operating specifications available online.

There are nineteen sizes of standard off-the-shelf ServoClass Couplings. These couplings are designed for automation applications, printing and packaging equipment, semi-conductor assembly, laboratory automation, medical equipment assembly, and for most products that use ball screws, linear actuators, and servo motors. Immediate shipment of most ServoClass Coupling popular bore sizes is available. Keyways and custom bores are also available with fast delivery, including bores for mounting on k6 and j6 tolerance shafts, commonly found on servo motors and precision gear reducers.