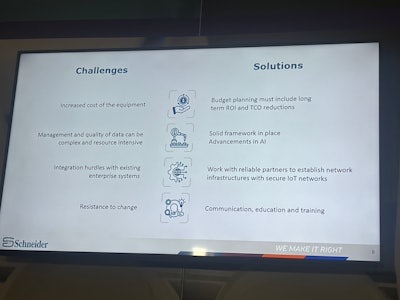

Predictive maintenance increases efficiency but is not without its challenges. Most can be solved with thoughtful planning and communication.

David Newcorn

Predictive maintenance is gaining traction in packaging and processing. Jamie Barber, Director of Product Development at Schneider Packaging, recently used the PACK EXPO International Innovation Stage to discuss how Schneider applies predictive maintenance in case packers and robotic palletizers. This approach leverages data collection and analysis to predict equipment failures, allowing for timely maintenance and minimizing unplanned downtime.