For more than two decades, MMC Packaging, Laval, Quebec, has supplied state-of-the-art, turnkey post-molding automation equipment to leading manufacturers of container caps and specialty closures. With more 1,000 systems in the field worldwide, the company is renowned for its work across a wide range of machines for cap lining (wadding), assembly, cap slitting, and closing, as well as vision systems and other custom automation equipment.

To maintain its leadership position, MMC Packaging’s engineers continually look for ways to boost their machines’ quality, performance, and ease of use. But though there is never a shortage of ideas and features, the PLC hardware at the heart of MMC Packaging’s control systems was being pushed to its limit, particularly when it comes to processing speed, system memory, data storage, and database capabilities.

“As we endeavored to modernize our systems, we needed more processing power and flexibility from our controller platform,” explains Mathieu Ouellet, MMC Packaging’s Vice President of Business and Product Development. “This meant a change of control technology was in order.”

Because the MMC Packaging upgrade strategy included a cuttingedge user interface with an ample selection of standard programming tools, the company saw a PC-based system as the way forward. Their research soon led them to standardize their control platform on TwinCAT 3 next-generation automation software from Beckhoff Automation, Minneapolis, Minn.

TwinCAT 3 supports all IEC 61131-3 programming languages, object-oriented programming (OOP), C/C++, and provides many other optional tools to programming engineers. In addition, TwinCAT 3 makes it possible to reserve individual CPU cores of a multi-core processor exclusively for TwinCAT. This feature, known as “CPU Isolation,” gives the full performance of the reserved cores solely to TwinCAT.

Rather than experiment with its new controls approach on a niche machine, MMC Packaging elected to implement the PC-based TwinCAT 3 approach on the company’s best-selling machine, the LM-270, which can cut and insert up to 300 cap liners per minute. In addition to handling all automation functions (e.g., conveyor control, reject functions, and confirmation of rejects), TwinCAT 3 allowed the engineers to improve the efficiency of the LM-270’s timing.

“With TwinCAT 3, manual intervention is minimized when performing timing changes on the machine,” says explains MMC’s Senior Electrical Designer Yan Letourneau. “Using automatic timing in software, the LM270 machine, with all its connected peripherals, can easily change speed on the fly and adapt the equipment rate to the volume and production needs of our clients.”

In addition to recording production data using TwinCAT 3’s Scope feature, the LM-270 leverages the same C6525 IPC as the centralized control hardware along with Beckhoff CP391x multi-touch Control Panels for the display hardware.

In addition to recording production data, the LM-270 leverages the same C6525 IPC as the centralized control hardware along with Beckhoff CP391x multi-touch Control Panels for the display hardware.

MMC Packaging also uses Beckhoff controls for its QTVision (Quality Through Vision) line of vision solutions. The QTVision is equipped with the CX2040 Embedded PC with Windows Embedded Standard 7 Operating System, TwinCAT 3 software, and EtherCAT as the system bus. The CX2040 features a powerful 2.1 GHz Intel® Core™ i7 quad-core CPU, which is more than capable to simultaneously run a wide range of automation, control, and data acquisition tasks.

“We previously used a ‘white box’ PC with the control programmed with C++ and had four or more cameras connected to it,” Letourneau says. “That PC couldn’t keep up with the vision programs, which caused a CPU load of around 70 percent. After moving to the CX2040 and TwinCAT 3, we went from 70 percent CPU load down to 30 percent with the CX2040. With four cameras, we can inspect up to 2,400 caps per minute and process up to 9,600 images per minute using the CX2040 without causing strain on the CPU.”

Control speeds in the low microsecond range are now commonplace for MMC Packaging, such as triggering cameras in the vision systems at 250 microseconds. And, with the new controls platform and interface, MMC Packaging can utilize 3D models and tutorial videos to supplement operator training and support.

“The ability to run all tasks including automation, PLC, motion control and the Windows-based graphical interface on a single device was a huge factor in favor of PC-based control as well,” Ouellet says. “Our 3D manual utilizes multitouch functionality programmed using C++ or C and includes pinch gestures to zoom in/out and view valuable equipment information and learn how to best operate the machine. We have many other ideas to provide other beneficial multi-touch features to MMC Packaging clients.”

EtherCAT “wears many caps” – for I/O, motion, and safety

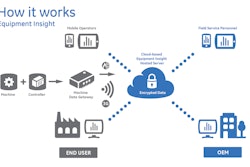

With a wider range of data logging and troubleshooting tools, MMC expects to significantly reduce its customer assistance intervention time and boost customers’ uptime as a result. Enhanced diagnostics capabilities and remote connectivity through the PC- and EtherCAT-based control platform are the key enablers here.

“TwinSAFE also demonstrates another added value from EtherCAT,” Letourneau adds. “Even for safety technology, I still use standard Ethernet cables. All the safety data goes through the EtherCAT protocol and there are TwinSAFE terminals throughout the machine. A system-integrated programmable safety solution is much easier to modify in the future as our machine designs evolve.” MMC Packaging mainly uses TwinSAFE today for e-stops, safety guards, integrated servo drive safety, and for safety measures on VFDs.

To implement the servo drive safety, MMC Packaging utilizes Beckhoff AX5000 EtherCAT servo drives equipped with AX5801 or AX5805 TwinSAFE drive option cards for safe stop functions (STO, SS1). The TwinSAFE-enabled AX5000 servo drives are paired to AM8000 series servo motors with One Cable Technology (OCT), which cuts the number of motor cables and connectors by 50 percent.

“Since the power and feedback is combined into one standard cable with OCT, this approach is far simpler and leads to a smaller machine footprint,” Letourneau says.

Ouellet adds that having OCT in MMC Packaging’s servo system, along with the EtherCAT I/O system and TwinSAFE, has been instrumental in streamlining machine designs.

“Instead of managing all control wires from the central units to all of our peripherals,” he says, “we now only have to wire a single Ethernet cable, which dramatically cuts our wiring cost and saves 20 to 24 hours of installation time per setup.”

MMC Packaging also uses EtherCAT High-Density gateway terminals in 16channel format also help MMC Packaging save space in electrical cabinets.

“With HD Terminals, we have replaced outdated terminals that had fewer I/O points and inefficient screw-type connections,” Letourneau says. “The EtherCAT I/O terminals we use today have efficient Cage Clamp connections which enable far simpler wiring. This streamlines machine setup, and results in shorter machine lead times. We reduced electrical cabinet space by more than 30 percent, and the savings can be directly traced back to the EtherCAT I/O system and compact PC-based controllers like the C6525 IPCs and CX2040 Embedded PCs.”

With the control upgrade to the LM-270 successfully complete, MMC Packaging is now working to develop and implement similar technologies across its product line, including assembly, sealing and slitting machines. Retrofits will also be made to existing MMC Packaging machines already in the field.