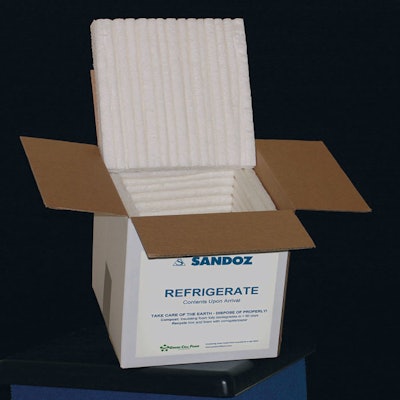

For years, Sandoz had used prevalidated expanded polystyrene cold chain shippers and ice packs to overnight-mail temperature-sensitive injectable liquids to U.S. customers from its Mechanicsburg, PA, distribution center. But when the company changed its outer shipping containers, it also switched to shippers made from Green Cell Foam™ cushioning material supplied by KTM Industries.

The 500,000-sq-ft Mechanicsburg facility serves as a third-party distribution operation for Sandoz products made worldwide. The facility receives boxes on pallets and manually fills product into them.

“We are a global company with operations everywhere, but once product arrives in our warehouse, we put it in a cooler and ship based on orders we receive from pharmacies, hospitals, or distribution centers across the country,” explains Mark Kuhl, packaging development and sustainability manager for Sandoz. “That’s when we have to break pallets down and ship individual cases out overnight to the point of use. These coolers keep product at the correct temperature range for 24 to 48 hours.”

Kuhl says the move to Green Cell containers, “was driven by the need to accommodate new products and to save money by doing our own validation, rather than pay for cold shippers validated by others.”

Walmart makes a difference

At the time Sandoz was considering shipping container options, Kuhl attended a Walmart sustainability-focused event at the retailer’s Bentonville, AR, headquarters. At the exposition, he learned about bio-based, biodegradable Green Cell Foam. “It’s a similar concept to other corn-based packaging material except KTM extrudes it into a corrugated-like panel,” says Kuhl.

After learning about Green Cell, Sandoz began to test the material for its insulation properties, which proved satisfactory. “It insulates very well, and we can use whatever case size we want and KTM will cut the Green Cell panels to fit that size,” says Kuhl. “If we wanted a unique size for a more traditional shipping case, we’d have to pay for the machine tooling and then wait weeks for the product. With KTM, we can call them and say, ‘We need a case just like the last one you did for us, but we want one that’s three inches shorter,’ and we’ll receive it within two weeks.” Sandoz began using the Green Cell in 2008.

Sandoz uses three different-sized containers incorporating the Green Cell-based material. KTM sources the corrugated shipping box from Landaal Packaging Systems, the company that also fabricates the Green Cell Foam into panels and assembles the containers for Sandoz. They cut 2-in.-wide Green Cell foam panels to line the bottom, top, and four sides within the shipper. During the development of the Green Cell insulated cooler, KTM asked for advice from Michigan State University's School of Packaging on the thermal capabilities and overall suitability for this type of application.The starch foam technology itself was advanced at MSU’s Chemical Engineering Department by Dr. Ramani Narayan.

“They're validated by running them through a 48-hour 'worst-case' temperature scenario for summer and winter shipments in the lower 48 states,” Kuhl explains. “We simulate a worst-case overnight UPS or FedEx shipment that is delayed 24 hours (hypothetical delay for blizzard or hurricane for instance). We understand the 'last mile' can be brutally hot on the back of a truck in August in Alabama, so we take this into consideration with our simulation.”

Benefits

More than ever before, pharmaceutical companies also have to monitor costs. Determining the return on investment from switching to the Green Cell Foam from EPS involves more than a sheer price comparison.

“Cost is important, but so is sustainability,” says Kuhl. “It's worth going with the ‘green’ solution even if it costs a bit more, because over the long haul, it normally ends up saving money and benefits the environment. For the initial Green Cell Foam project, when we switched from prevalidated coolers to the Green Cell, we saved $300,000 in the first year,” he concludes.