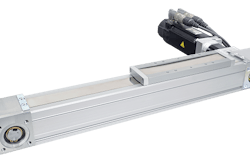

SMAC Moving Coil Actuators has announced that the differential features the SMAC Voice Coil Actuator is known for will be available for an OEM's requirements by "dropping into" the form, fit, and function of their existing system. This process, called “MCA Inside,” is for helping OEMs with an install base and/or an existing design for embracing the company to solve problems with minimal inconvenience in making the change.

-

Parts are manufactured using precision plates designed to have minimal machining required.

-

Drilling, tapping, and reaming processes—which are meant to offer an actuator with the size and mounting arrangements of a customer’s current system.

-

Customer specified housing—SMAC can install their standard Moving Coil Piston and Magnet Assembly into a customer's existing housing design.

-

Built-in controller options which are designed to offer internal programming and decrease wiring with 24vdc/48vdc PLC I/O operation.

SMAC’s MCA Inside, with the Moving Coil Actuator, is made to replace problem actuators on currently produced machines. The actuator can also be fit into particular required spaces on new machines, according to the company.

Some changes in design that the company has performed to create MCA Inside include replacing a ball-screw stepper system with a "bolt-in" LBS17 with cross rollers which is supposed to result in more precision, longer life, and quieter motion. They have also replaced throw away pneumatic air cylinders with the "drop-in" CBL actuator with build-in controller on an eject application, to limit downtime and set-up. Lastly, SMAC has replaced a moving magnet linear motor with a rotary that has a SMAC CBR100 electric cylinder with Z-theta motion in one unit on an OEM capping machine.

SMAC Moving Coil Actuators are made to have programmable and controllable position, velocity, and force, higher accelerations, cycle life over 100M, and a patent-pending “Soft-Land” capability. The Soft-Land capability is is intended for performing fragile part assembly, measurement, moving objects, etc.These are designed to provide real time feedback.