This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Harpak-ULMA, a provider of smart, connected packaging solutions, has announced a strategic U.S and Canadian distribution agreement with Cabinplant to partner for its sales, services and support for the company’s renowned multihead fixed-weight packaging solutions.

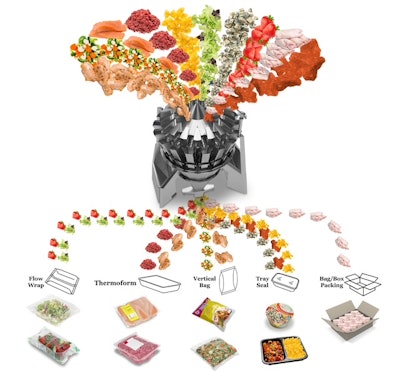

Cabinplant provides innovative, efficient, and tailored food processing solutions capable of managing the entire pre-packaging process; from initial bulk product distribution to product feeding and highly accurate portioning and weighing for fresh, frozen or processed meat, poultry, dairy, seafood, fruits, vegetables, convenience foods—and even pet food—packaging processes. Combining Cabinplant’s capabilities with Harpak-ULMA’s existing slate of smart, connected packaging platforms, automation, package design, accredited training, and national support network results in one of the most comprehensive, modular portfolios of integrated, automated food packaging solutions available from a single vendor today in this region.

“Expanding our solution footprint to embrace more units of production for a customer makes a lot of sense because it lifts the burden of interoperability from the buyer”, commented Kevin Roach, Harpak-ULMA CEO. “A single, automated pre-integrated solution reduces the risk and time typically associated with patching together technology from multiple vendors. Not only that, but it also eliminates onsite testing iterations, improves machine performance, simplifies diagnostics, and streamlines the entire planning, install and startup process to deliver optimized production sooner. That translates into faster time to market, better ROI, and faster payback than more complex, multi-vendor solutions—on top of the return customers realize by implementing more efficient and accurate fixed weight packaging automation.”

The agreement significantly increases the range of automation and packaging combinations available to Harpak-ULMA’s served markets. Cabinplant’s North American customer base gains access to pre-integrated Harpak-ULMA packaging platforms as well as the company’s extended services offerings such as package design, Harpak-ULMA [training] Academy, and OEE monitoring, plus an extensive North American support services and parts supply operation.

The value of multihead weighing is derived from a combination of automated pre-packaging product processing, distribution and feeding, highly accurate portioning, and dramatically lower manual labor costs.

Lars Ryholl, Cabinplant CEO, commented, “Delivering food products at a fixed weight without automation poses significant challenges due to the natural variability in product size and yield management complexities. Traditional, manually intensive packaging processes are notoriously inefficient and costly, both in terms of labor and product “give-away” which can run up to 5-6% of packaging yield. Cabinplant’s Solutions ensures the customer the lowest give-away on the market — which is substantial in terms of profit optimization, not to mention the significant labor savings.”

In keeping with Harpak-ULMA’s philosophy of delivering smart, connected packaging solutions, Cabinplant’s solutions will be pre-integrated to allow for seamless plug-and-play connectivity with the company’s existing automation and packaging platforms. A consistent digital thread across production enables real-time packaging visibility, exposing key information to advanced manufacturing software applications designed to drive production performance improvements. Harpak-ULMA’s OEE monitoring and Augmented Reality Solutions will expand to include the Cabinplant line. In addition to ensuring seamless connectivity with its own automation equipment, the company plans to offer open, pre-configured integration compatible with virtually any vendor's packaging equipment. Integrated systems are not only easier to operate and maintain, but they also improve overall solution modularity, elevating Producer flexibility, thus improving their ability to meet evolving retailer and market demands.

Roach added, “We’re thrilled to welcome Cabinplant to our family of packaging platforms and automation solutions. It’s a value-add play for both existing and prospective customers. We are particularly excited by the variety of feeding and weighing configuration options they create for our tray seal, thermoformer, vertical form fill/seal, flow wrap and carton solutions. That kind of customizable, modular packaging approach is very much in line with how we see the market evolving across every one of the industries we serve. We believe that the ability to deliver highly accurate, automated portioning is very much in demand, not only in case-ready applications, but in fresh or frozen prepared foods and packaged meats or seafood. The fact that their accuracy is so good as to all but eliminate product giveaway, will turn a lot of heads.”

Be sure to visit Harpak-ULMA at PACK EXPO International 2024 this November 3-6 at Booth N-4736 in McCormick Place in Chicago, IL.