The Paxiom Group is made up of four independent companies. Three of them make but don’t sell. One sells but doesn’t make. Different? Who cares? It works like a charm.

When Louis Taraborelli founded WeighPack Systems in 1991, it’s unlikely he could have predicted that the Montreal-based firm would one day be part of a four-pronged packaging machinery entity with an unusual way of going to market. But that is indeed what WeighPack Systems—along with sister companies CombiScale, Eagle Packaging, and Paxiom—has evolved into.

Each independently operated company brings something different to the table. WeighPack manufactures primary packaging machinery, including filling, bagging, wrapping, and conveying solutions. Miami-based Eagle Packaging, acquired by WeighPack in 2008, is a maker of secondary packaging solutions: case/tray forming, case packing, and robotics. And then there’s CombiScale, launched in 2006, which builds multihead weighers and combination scales in both Montreal and Shanghai.

None of these three has its own sales organization. That’s where Paxiom comes in. While the other three groups focus on manufacturing, Las Vegas- and Toronto-based Paxiom is essentially what knits the four firms together, because Paxiom is the sales division that represents the machinery made by the other three.

That alone would make the Paxiom Group considerably different in the universe of packaging machinery OEMs. Further differentiating it is management’s strong belief in what it calls its Paxiom System Centers. The first of these opened in Las Vegas in 2002. Now there’s one in Shanghai and Toronto, too. Much like a well-appointed automobile showroom, this is where customers can not only see but actually use the machinery, test their products, and make sure the Paxiom solutions meet their expectations. Each visit is tailored to the customer’s personal needs. And factory-trained representatives are available to discuss specific applications, offer training, and provide necessary expertise.

The idea is to design, manufacture, and integrate state-of-the-art packaging solutions at exceptional value, while developing lasting partnerships through great quality and excellent service. Covered is a broad range of filling, bagging, case erecting, and palletizing machines with models to suit every application, production requirement, and budget. With five globalfacilities—Montreal, Toronto, Miami, Las Vegas, and Shanghai—Paxiom Group has delivered thousands of packaging solutions throughout the world and lets customers work with one manufacturer, one service department, and one point of contact.

So why go to market as autonomous entities? “Each of our companies has its own standalone value, brand recognition, expertise, and customer base,” says Nicholas Taraborelli, son of the company’s founder and Paxiom’s vice president of sales. “Each entity thrives as its own business while offering the best buying experience through our Paxiom System Centers.”

System Centers

Let’s get back to those Paxiom System Centers, because they’re the straws that stir the Paxiom drink. Taraborelli calls them “the most exciting part of our business.”

“It’s a fact that a manufacturing environment is one with a lot of distraction, making it difficult for clients to focus on the equipment they need to consider,” he says. “Our showroom settings are designed for the ultimate consultation experience. They range in size from 10,000 to 15,000 sq. ft., and each includes more than 30 packaging machines and more than $2 million in finished machine inventory. We modeled them after the personalized buying experience that’s offered in the retail industry. After all, these are long-term investments of high value, hence we ensure that the appropriate amount of time is invested with our clients to be certain that they find the right solutions for their needs. Our service includes hotel or airport pickup, customizing our showroom per the requirements of their project, and ensuring we have all the available resources to thoroughly run product while the customer is with us.

“Investing in packaging automation equipment can be daunting, especially as a first-time buyer. There are a lot of steps in the decision-making process. We feel strongly that we can provide customers with the best experience possible by letting them see the machinery in person, test their product, and validate for themselves that this is the right packaging solution that meets their requirements—all in a setting that’s optimized to make the buying experience less stressful. It really comes down to inventory and environment. There’s a lot of competition out there, and how we separate ourselves is by providing customers this unique buying experience.”

Because being a single-source supplier is such a key component in the way Paxiom Group goes to market, it’s fair to ask which of the three machinery builders handles integration responsibilities when a new line is installed. Taraborelli says it varies from case to case. If it’s largely an Eagle integrated solution, they will manage line integration. If it’s WeighPack or CombiScale, the same practice follows.

Ute Mountain Tribe Farm & Ranch Enterprise offers a good example of how this plays out (see pwgo.to/1741). At this rural Colorado facility, corn meal is filled into pre-made pouches by a WeighPack auger filler feeding a Weigh-Pack Swifty Bagger. Secondary packaging—lane diverting, pouch orientation, case erection, case packaging, and case sealing—is done by machines made by Eagle Packaging. Eagle also supplied the robotic palletizing. In this particular line, some of the more challenging issues revolved around secondary packaging and robotics, so Eagle bore the responsibility for line integration.

200-strong

The group employs more than 200 people and generates between $20 and $50 million in annual sales. It’s a global player with geographic sales and support in North and South America as well as Australia, India, and Asia Pacific. In those markets are 15 traveling field service technicians. As for sales, about 80 percent are accrued directly and the rest through distribution.

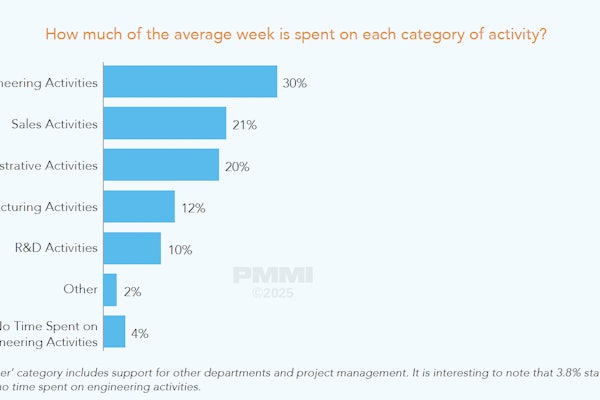

When it comes to new product development, Taraborelli says it almost always starts with a customer’s needs. Once a project reaches R&D, three key questions are asked. First, is it a one-off solution for this client alone? Second, might this client place multiple orders for this product? And third, is there a global market for this machine? All three questions are carefully weighed, and the answers shape the project if it’s decided to move ahead with it.

Taraborelli estimates that about 80 percent of the machines they build would fall in the off-the-shelf or standard category. “We pride ourselves on being able to offer our clients quicker delivery times than industry standards,” he points out. “Hence we have created a standard product line that is configurable for most every client need and project specification.”

Other sources of new ideas about packaging machinery, in addition to customer requests, are international trade shows like interpack and PACK EXPO. But Taraborelli also emphasizes how educational and influential routine business travel can be. With offices and people in such far-flung places, a certain amount of globetrotting is inherent in Paxiom’s corporate DNA. Management makes a concerted effort to make sure people are paying attention to what’s in the supermarket from one region to the next. “We’re seeing a lot of fruit getting individually wrapped these days in Italy and France,” Taraborelli points out by way of example. “This trend is on its way to North America, and we’re making sure our people in R&D are preparing for it.”

Taraborelli says the firm invests about 10 percent of sales in R&D. “As a group we employ more than 30 engineers,” he adds. “Each of our three manufacturing companies has its own engineering department, and though they operate autonomously, at times there’s a lot of cooperation and sharing of resources.”

When it comes to finding employees, Paxiom once again benefits enormously from being as geographically dispersed as it is. The cities where it’s located—Toronto, Montreal, Miami, Shanghai, Las Vegas—are all dynamic cultural, educational, and social hubs where talent is, if not abundant, then certainly available. Languages spoken in these places are also numerous, and in today’s global marketplace, who wouldn’t want an employee base with a collective command of not just English and Spanish but also French, Cantonese, Mandarin, and more?

One smooth flow

As for customer needs assessment, project management, systems integration, and Factory Acceptance Tests, the goal is to have them flow as smoothly as possible one to the other. Needs assessment is essentially an interview process aimed at verifying what the project requirements are. “As important as it is to provide the right machine for the specific application is to understand customer expectations, including labor reduction, increased productivity, and overall corporate goals and priorities,” says Taraborelli.

Once a purchase order is in hand, a project manager is assigned who will follow the project right through to Factory Acceptance Test, training, and on into installation in the customer plant, where the training process continues. The project manager pays close attention to engineering drawings as they evolve and makes sure things like container samples are readily available when the time comes.

So what does the future hold for Paxiom Group? Plans are definitely in place for additional Paxiom Service Centers, though Taraborelli prefers not to tip his hand as to where they might be. Whatever city they wind up in, it’s a safe bet they’ll be shaped by the same core philosophy upon which the rest of the organization rests, a philosophy Taraborelli sums up this way: “Be ready to adapt and be driven.”