The American chemical industry is an $801 billion enterprise that has grown significantly over the past decade, according the American Chemistry Council, and U.S. exports are expected to rise by 4.4 percent in 2017. This increased volume only exacerbates an existing need for global harmonization and standardization over how chemicals are labeled, something that could be critical to worker safety the world over.

The industry’s steady growth forced OSHA to adopt new hazardous chemical labeling requirements for packaging in 2012, during its revision of the Hazard Communication Standard, 29 CFR 1910.1200 (HCS). This affected everything from raw materials to finished products; from steel barrels of concentrate to household cleaners containing flammable or toxic chemicals. The revisions align OHSA’s standards with the United Nations’ Globally Harmonized System (GHS) of Classification and Labelling of Chemicals, and chemical manufacturers and end users were given until June of 2016 to comply.

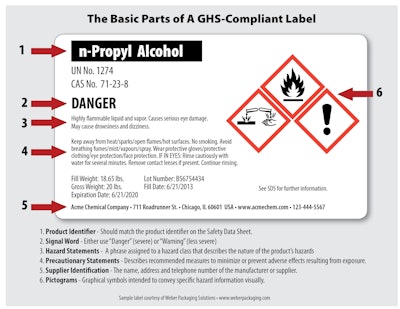

GHS standardizes labels so they clearly identify, via pictograms, the chemicals or chemical categories that handlers are dealing with. While the new standards mainly affect chemical manufacturers themselves, or employers of workers who handle or export hazardous chemicals, packaging OEMs that manufacture labeling systems have been tasked with creating GHS-friendly equipment for compliant labeling.

Existing labeling standards cause confusion

But many OEMs were left scratching their heads, unsure how much of the onus for adhering to these standards fell to them, compared to their chemical manufacturing customers. Further muddying the waters, they wondered how these new standards meshed with existing standards.

One confusion-causing culprit was the Marine Immersion BS5609 standard, which had long been associated with the material constitution or stock of labeling to be used on chemical shipping containers. New GHS standards also apply to those steel barrels being shipped overseas, so many OEMs and end users alike made the mistake of conflating the two standards, and assumed that GHS held a similar label material requirement. David Holliday, director of product marketing, ID Technology, a Pro Mach Company in West Chicago, Ill., says this was a general misconception that permeated the industry.

In fact, the new GHS standards only dictate the size and informational content—such as the pictogram or color—of the label for a hazardous chemical. GHS does not currently specify the label’s material, or ask for certification for hazardous chemicals that are not being exported.

Marine Immersion BS5609, on the other hand, stipulates a label’s physical material requirements and dictates use of pressure sensitive labels on steel drums holding hazardous chemicals that are shipped overseas. These labels also need International Maritime Dangerous Goods (IMDG) certification, and require a special label stock and ribbon that must withstand ocean conditions for three months and remain legible.

Holliday and ID Technology, a labeling applicator equipment manufacturer, understood the inherent differences between the two standards, but also anticipated the frequent overlap and need for both to work hand-in-hand. So, even when he found GHS adoption to be relatively tepid compared to BS5609, he still wanted to offer a machine that could simultaneously incorporate the two standards.

His company partnered with QuickLabel Systems, Schaumburg, Ill., to create an automatic applicator that prints full color, GHS-compliant labels that are durable enough for BS5609 compliance. This got ID Technology out in front of GHS, while continuing to serve the larger petrochemical market.

GHS enforcement up in the air

But why the unenthusiastic adoption of the new standard among end users?

“No one seems to be enforcing GHS to the extent that BS5609 is being enforced,” Holliday says. “End users have figured out they need to comply with BS5609, they have made some investments, and we have sold to those companies.”

Many government agencies are currently feeling some turmoil in the wake of the new administration, and resources may be scarce for some government offices.

“People are still waiting to see what happens,” says Rick Fox III, director of engineering services, FOX IV Technologies, Export, Pa. “We haven’t heard of any GHS enforcement, and if you don’t have a lot of enforcement on something, it can lessen the urgency to get it done or comply before the deadline.”

According to Kimberly Darby from OSHA’s office of communications, chemical manufacturers and importers of hazardous chemicals are responsible for ensuring chemical labels comply with GHS requirements. If a distributor changes the label, the distributor then becomes the responsible party. Therefore, the chemical manufacturer and end user of packaging equipment is more likely to be at fault than the OEM. But being less likely to be at fault is hardly an assurance, so OEMs can take little comfort there.

Fox says that while it is necessary to understand customer demands and provide compliant equipment, FOX IV, a labeling system manufacturer, is forced to place the responsibility of compliance in the end user’s hands.

“Even if we are helping our customers out with choosing label stock, we want to give them recommendations and make sure they stay in compliance, but let’s say a customer comes to us with pre-printed labels, we don’t research to find out whether or not these are compliant labels. That’s the customer’s responsibility,” Fox says.

While a clear enforcement plan from OSHA is needed for OEMs to be able to gauge how they can better serve their customers, OEMs continue to take new equipment orders, even past the compliance deadline.

OEMs wade into GHS, navigate inconsistent demand

Weber Packaging, Arlington Heights, Ill., manufactures label application systems and labels that can be found on everything from household chemicals to steel drums of petrochemicals. The OEM also built its own GHS labeling software when it first heard that the standards were changing.

“Our customers’ way of complying prior to this regulation was by doing everything that OSHA required: a warning, company name, and an address. But now they have to use pictograms, and there could be different combinations of pictograms depending on the chemical formulation,” says Paul Johnson, packaging solution specialist. “We incorporated the Epson C831 printer into our equipment because it gave our customers a lot of flexibility since they only had to buy a blank label from us, and they could control everything else through our GHS software.”

Weber doesn’t retrofit any existing systems when accommodating the upgrade to new standard-friendly equipment. The OEM recommends that its customers completely switch from thermal transfer printers to new color inkjet printers—like the Epson—replacing thermal transfer ribbons with inkjet cartridges and using unique label materials that accept the inkjet ink. But Weber has been stressing that it offers everything needed to be compliant in one package with its GHS labeling software.

“The biggest push for new equipment was in 2015,” Johnson says. “Companies are still looking for labeling systems, and we are catering to those who are behind in compliance, but also those who want to improve their process.”

ID Technology also jumped at the opportunity to build compliant equipment.

“We now have a product line of GHS-compliant printers, which is a combination of printers we make and printers from other vendors that we sell, and we have sold a couple of each,” Holliday says.

Since ID Technology serves markets like healthcare and chemical, which are mostly standards-driven, Holliday was ready to create compliant equipment as soon as the standards were announced. While new equipment demand was steady, Holliday says it was less of a push than ID Technology expected.

“We get a couple of orders every month, but we expected to get more inquiries than we currently get,” Holliday says. “This didn’t take off to the extent that people thought it would. We spent a lot of time getting things together because we were thinking GHS was going to be a big boon for labeling.”

Johnson agrees. A large contingent of end users are bound to comply with GHS standards. The companies manufacture anything from petrochemicals to consumer products, like house-hold cleaners, which is why the lack of demand has Johnson and Holliday puzzled.

FOX IV Technologies hit the market with its GHS-compliant Tandem II two-color label printer-applicator for next-off GHS labeling and configurations of their standard products, a bit later, because Fox says the new standards were poorly communicated.

“We are currently producing machines specifically for GHS labeling, but back when the standard was first introduced, we were taking orders for GHS compliance labeling without the customer mentioning that it was for GHS,” Fox says. “The customers would ask for a print and apply machine for a barrel, but it wasn’t until we saw the labels coming in that we noticed that they were GHS-compliant labels.“

And even though the compliance deadline passed for end users in mid-2016, Fox says his company got a wave of new orders at the end of 2016. So Fox was not alone in less-than-immediate adoption.

Opportunity for OEMs

Coming up on a year post-compliance deadline, OEMs and end users await enforcement plans to be put in place by OSHA. Still, OEMs should expect to see orders from chemical manufacturers and end users who haven’t yet complied.

Johnson says Weber Packaging is seeing a lot of end users who want to upgrade their current GHS-compliant systems to improve the process. He recommends that OEMs spend this unenforced period researching the standards so that when the wave of orders from end users who are behind on compliance roll in, OEMs can be prepared with solutions.

“Understanding the regulations is critical,” Johnson says. “There is a lot that goes into the standards and how they apply to our customers, but we worked with our partners, and our problems aren’t as big as our customers’ because they are the ones that have to compile all this information and implement a new labeling system.”

To learn more about OSHA’s GHS standards, visit: www.osha.gov/dsg/hazcom/index.html

To learn more about labels and pictograms on GHS labels, visit: www.osha.gov/Publications/OSHA3636.pdf

To learn more about BS5609 Marine Immersion standards, visit: www.smitherspira.com/services/materials-testing/adhesives-and-labels/subsea-adhesion