The public's interest in "natural" remedies for common illness symptoms has flourished over the past few years. That makes it a good time to be in the medicinal herbal tea business. Just ask the folks at Traditional Medicinals.

"Annual growth in this category over the last three years has averaged a good fifteen to twenty percent," says Lynda Sadler, president and co-owner of Traditional Medicinals. "It's partly because these products, which originally were aimed at small outlets like health food stores, are now entering grocery and drug stores and other mainstream retail outlets. That means the room for growth is sizeable."

To keep up with all this growth, the firm has had to invest in tea bagging machines on an ongoing basis. It now has five of them lined up cheek by jowl in its Sebastopol, CA, headquarters. Supplied by IMA (Bologna, Italy), they not only form and fold filter paper around the correct dose of tea, they also staple a paper tag to a string and staple the string to the tea bag. The machines also form and seal a coated paper wrap around the tea bag, collate wrapped bags for insertion into cartons, erect carton blanks, and insert 16 wrapped bags in each carton before folding the carton closed. Ten cartons are produced by each machine each minute.

Just as impressive is the Flex-Link (Bethlehem, PA) conveyor system that carries filled cartons away from the tea bag makers to one of two case-packing stations. The Flex-Link system consists of five conveyors running parallel to one another. These five conveyors deliver the cartons to a single perpendicular conveyor that takes each carton off at a right angle to the left or right, depending on which case packing station the carton is directed to.

"This conveyor arrangement lets us run one tea on all five IMA machines or split production and do one blend on some of the machines and another blend on the others," says maintenance engineer Alvin Hasin, who has been steadily upgrading tea bag packaging at Traditional Medicinals over the past four years.

The most significant improvement in the line came in March of 1995. That's when the Flex-Link conveyor system was installed. At the same time, a second checkweigher, carton gluing station, ink-jet case coder, and top-and-bottom case taper were all added. And to tie it all together, Hasin replaced the conveyor control system, a hard-wired system of relays, contacts and switches, with a programmable logic controller that operators access by means of a Smart Touch operator interface from Total Control Products (Melrose Park, IL).

"The problem with a hard-wired system is that any time you want to change the configuration, like adding or replacing a checkweigher or conveyor, you wind up removing and replacing a lot of wiring," explains Hasin. "With the touchscreen, all you do is write a new software program and match that with your PLC. It's a great step forward for us."

Another big contributor to the tea manufacturer's efficiency is the glue delivery system that glues paperboard folding cartons shut. On most IMA machines, glue is applied before the carton is discharged from the IMA machine. Hasin didn't like this arrangement because if the downstream checkweigher rejects a carton that contains less tea than it should, the carton has to be destroyed before the problem can be fixed. So on both left and right sides of his tea packaging operation, Hasin placed the glue-gun stations after the checkweigher. If a carton is light, it's a simple matter of adding what's necessary and sending it back into the line. Hasin also appreciates that the glue guns are in a spot where they won't gum up the tea bagging machines.

But these advantages didn't come without some extra effort on Hasin's part. The target the glue guns must hit on each carton is so small that no commercially available gun could dispense glue in a fine enough bead.

"We shoot a bead of glue that's six thousandths of an inch in diameter by about a half inch long, and we get it in a space that's less than half a millimeter," says Hasin. "It was difficult finding glue-gun tips with a small enough orifice for such an application, so I made my own. I also made them longer than usual."

Upstream from the glue stations on both left and right sides of the line is a checkweigher from Ramsey (Minneapolis, MN). According to Hasin, its compact profile, compared to others he evaluated, made it easy to position the checkweigher where he needed it.

"It's also easy to set up and use," he adds. "And it has an output device that allows us to print at a remote station the production information that would otherwise have to be written down on a sheet of paper."

Following checkweighing and carton gluing, cartons are manually case packed. Supplied by Mid-Cities Paperbox (Bell Gardens, CA), cartons are a 16-pt board printed on a sheet-fed offset press in six colors plus varnish. Also printed in simple black on the inside of the carton are brewing directions and quotes from authors writing about plants.

Robotic packing on the way

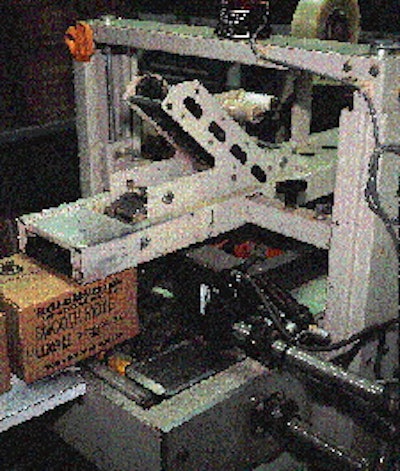

Typically cartons are packed into a standard kraft corrugated shipper. Case packing at this point is a manual operation, though Hasin is looking into robotic packers. Operators pack six cartons in a case and send it through a 3M (St. Paul, MN) top-and-bottom taper. Mounted on the discharge conveyor of the taper is a Marsh (Belleville, IL) ink-jet unit that prints name of product, expiration date, and lot code on one side.

"Soon we'll add a bar code that customers can use for inventory control, which is one reason we went with the Marsh unit," says Hasin. "They said it would print a good bar code consistently." Hasin will also mount a second printhead on the discharge conveyors of both case tapers so cases can be printed on both sides.

Though most of Traditional Medicinals' production is packed in corrugated shippers with plain kraft liners, there is one alternative approach. It's a beautifully decorated master container that holds 30 cartons of a single tea.

"We put our best sellers in this master case and suggest that retailers stack them for promotions," says Sadler. "As they say in the retail trade, 'Stack 'em high and watch 'em fly.'" Sadler adds that the display shipper has been in use for about two years now.

Supplied by Allwest Containers (South San Francisco, CA), the shipper has a tearaway front panel that lets individual cartons show their stuff. The 32-lb ECT case is made of B-flute corrugated. Its preprinted liner is 12-pt SBS printed offset in four colors.

Running around the clock during its peak winter season, Traditional Medicinals packs about 6귔 six-carton cases per day. Exports reach markets in Canada, Asia, and Europe. A rigorous preventive maintenance program helps ensure those markets will get the product they need, when they need it.

"We have very little downtime," says Hasin. "We work on the tea bag machines every afternoon from 2:30 to 3:30, cleaning, inspecting, replacing parts if needed. Each of these machines has about 10ꯠ moving parts, and if one is off by a tenth of a millimeter, you won't get a good tea bag." Hasin adds that he inventories about $35ꯠ in spare parts-knives, grippers, center wheels-for the IMA machines.

"One of our IMA machines is 15 years old," he continues. "By keeping it up, maintaining it, and rebuilding it when necessary, we still make tea bags on it as good as when the machine was new." Adds Sadler, "A staff of well-trained operators and a strong quality assurance team help guarantee a quality product."

Anticipating continued growth for the foreseeable future, the firm is busy with a plant expansion that will eventually allow the addition of more tea bagging machines.

"For 23 years we've invested and reinvested in the company's growth," explains Sadler. "That's how we'll continue to manage it."