Low piece-count weighing applications—think of larger granularity items like ketchup packets or IQF fishsticks—can be tough with standard combination scales in bagger/weigher formats due to overfilling of the buckets.

“If you’re trying to have the scale count to two pieces, and a single bucket has four pieces in it, that lane will automatically be inhibited since it is an overweight,” said Dustin Literski, General Manager of OEM sales at Yamato, during the video demo. “When this happens, the overfill buckets must be removed manually. If you don’t remove overfill buckets manually, the scale will begin losing combinations. Each head that is an overweight reduces combinations by half.”

To address this issue, Yamato Scale’s patented new SVR counting system, designed specifically for low piece-count weighing applications.

The problem

When targeting low counts, the feed to the scale is crucial to prevent bucket overfeeding. Depending on the products' characteristics—again, flat, rectangular ketchup packets were used in the demo, or IQF fish sticks—dams or shingling in the buckets can occur, which are destined to create overfills requiring manual removal. If they’re not addressed by an operator, a common occurrence is product being caught in the seal, a recipe for downtime and wasted film.

Operators on traditional combination weighers might compensate by slowing the feed to a crawl, and may even cause the scale to stop as it waits for more product. This is highly inefficient use of capital equipment.

Also, product rejects are an issue since that occurs beneath the scale at an operator level, making them hard to reintroduce into the feed system. Inline metal detection is thus compromised. Plus, the whole workaround system requires adding a collection bucket that will reintroduce rejects back into the top of the scale, adding height to the system.

“For every rejected overweight, one to two cycles are missed,” Literski said. “What we mean by this is if you are needing to reject overweight buckets, one out of every 10 cycles, the overall system will only be running at an 80 to 90 percent efficiency since the rejecting process can take time. Some pneumatic systems can take even longer.”

The solution

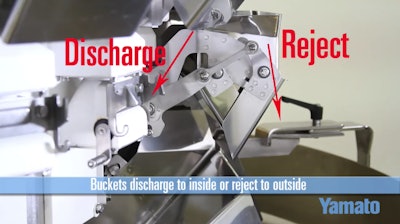

Yamato’s SVR system, with rotating reject ring at the top of the scale. Using dual-acting weigh buckets that discharge correct counts to bagging on the inside of the system, and reject to the outside to the reject ring, the system allows replenishing the system with rejects above the discharge into bagging.

Another notable feature of this system is the ability to auto-reject buckets that haven’t been used in a combination in sometime—consider IQF fish sticks that may begin to thaw the longer they’ve been waiting to be combined into a count. Gummies are another example, since they like to tend bind and clump when not moving.

This system is can be used in secondary packaging, too, for filling corrugated shippers with accurate counts of flowwrapped candy, for instance.

To view the demo in its entirety (available through March 31, 2021), and add Yamato Scales to your MyConnects Planner, click here.