Carleton Helical Technologies

Doylestown, PA 18901

Carleton Helical Technologies is a leading provider of packaging machinery solutions with over 40 years of experience. We specialize in the design and manufacturing of advanced container handling solutions, delivering reliable systems to industry needs.

CHT products are trusted globally for their innovative engineering and reliability, specializing in Ionized Air Rinsers, Feedscrews, Invertors, Helical Denesters, and Belt Drive Units. At the heart of our machinery is cutting-edge technology, ensuring superior performance on production lines.Our Ionized Air Rinsers efficiently clean containers before they move to downstream applications, using ionized air for optimal cleaning and preparation.Feedscrews and Feedscrew Drives are precision-engineered for diverse tasks such as combining, dividing, rotating, collating, metering, and nesting/de-nesting. Utilizing advanced software, they ensure unparalleled accuracy in moving containers along production lines.Invertors offer quick, efficient container inversion and positioning, with a compact 12-24 inch footprint that easily integrates into existing conveyor systems. Designed for versatility, they feature color-coding, quick changeovers, and support for inspections, product mixing, cleaning, and container rotation.Helical Denesters provide an efficient solution for separating stacked products like cups, bowls, and trays. They offer both manual and automatic loading, seamlessly discharging individual items onto conveyors, platforms, or lead stations for smooth transition to the next production phase.Belt Drive Units are built for durability and versatility in heavy-duty applications across industries. Their modular design integrates easily with existing conveyor systems, and the belts are capable of handling both heavy-duty and delicate containers.Our products offer reliable, high-performance solutions tailored to meet the unique needs of every production line.

Carleton Helical Technologies (CHT) warrants that each piece of machinery manufactured at our facility will be free from defects. If any item is found to be defective in material or workmanship under normal intended use and maintenance, CHT will, at its discretion, repair or replace the defective item at no cost to the customer. All manufacturer machine components are covered by the respective manufacturer’s warranties.

At CHT, we take great pride in delivering exceptional customer service for all our packaging machinery. From the initial design by our engineering team to installation and beyond, we stand behind the quality of our products. Our Customer Service department works closely with clients to ensure that all CHT machinery operates at peak performance. We recognize that downtime can be costly, which is why our team is always available to provide support and troubleshooting whenever needed. With CHT packaging machinery, you can be confident in making a reliable investment for your production line, supported by outstanding customer service.

Carleton Helical Technology is your one-stop-shop for all your custom packaging machinery parts, engineering and manufacturing needs. We specialize in providing high-quality engineering and manufacturing services for custom packaging machinery parts that are tailored to your specific applications. Our in-house team of experts uses cutting-edge technology and equipment to design and manufacture custom packaging machinery parts that meet the highest standards of quality and performance. We also perform Factory Acceptance Tests (FATs) to ensure that all parts meet your specifications before shipping them to you. With Carleton Helical Technologies, you can trust that your custom packaging machinery parts will be delivered on time and on budget. Contact us today to learn more about our services and how we can help you achieve your packaging goals.

Carleton Helical Technologies (CHT) has been a trusted partner in the packaging industry since 1979. Initially a custom engineering facility, CHT has built a solid reputation for designing and manufacturing high-quality container handling solutions for a variety of industries.

CHT products are used globally, with a specialty in Ionized Air Rinsers, Feedscrews, Invertors, Helical Denesters, and Belt Drive Units. Technology is not just part of our name—it’s embedded in every piece of machinery we produce. Leveraging the latest engineering advancements, our team of experts designs every component to ensure superior performance on production lines.

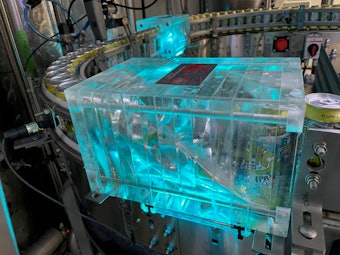

Our Ionized Air Rinsers efficiently clean containers before they enter downstream applications, utilizing ionized air for optimal cleaning. This ensures that your containers are thoroughly prepared for the next phase of production.

Our Feedscrews and Feedscrew Drives are engineered for precision, perfect for a wide range of applications such as combining, dividing, rotating, collating, metering, dwelling, and de-nesting. With state-of-the-art software, our engineers create solutions that move containers with unmatched accuracy.

Invertors are designed for quick, efficient container inversion. With a compact footprint (approx. 12-24 inches), they integrate seamlessly into conveyor systems, with minimal modifications. Featuring color-coding and quick changeovers, these versatile units support inspections, coding, product mixing, cleaning and container rotation.

Helical Denesters provide an efficient solution for separating stacked products like cups, bowls, and trays. Capable of both manual and automatic loading, they separate stacks and discharge individual items onto conveyors, platforms, or lead stations, ensuring a smooth transition to the next production stage.

Belt Drive Units are engineered for durability and versatility, ideal for heavy-duty applications across industries. Their modular design makes them easy to integrate into existing conveyor systems, while the belts are designed to handle a variety of containers—whether heavy-duty or delicate.

As a member of PMMI, CHT specializes in providing equipment integration solutions for both OEMs and consumer packaged goods (CPGs). We are committed to delivering high-performance machinery and components that incorporate both cutting-edge and proven technologies, and we look forward to the opportunity to serve you.