This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

At PACK EXPO Las Vegas, Emerson will showcase its Floor to CloudTM packaging automation solutions. The company also will sponsor two events: the annual Packaging & Processing Women’s Leadership Network (PPWLN) breakfast and the Amazing Packaging Race. All women registered for PACK EXPO Las Vegas are invited to the free PPWLN breakfast and program on Tuesday, September 12, at 7:30 a.m. in Room N-247. Following the breakfast, attendees will have the opportunity to take a private show floor tour and participate in a Q&A with Lisa Propati, vice president and general manager of Weiler Labeling Systems, as well as other packaging executives. As part of the Amazing Packaging Race, teams from U.S. colleges, trade schools, and universities will race to complete tasks and solve problems at booths across the PACK EXPO Las Vegas show floor.

Product highlights include:

The Aventics Series Advanced Valve (AV) system with advanced electronic system (AES) is the first pneumatic valve system with an integrated Open Platform Communications Unified Architecture (OPC UA). The AES helps with interoperability challenges and accesses data more easily, while the digital twin integration improves productivity efficiency and reduces costs.

Aventics Series AF2 flow sensors monitor air consumption in pneumatic systems, enabling rapid intervention if leaks occur to help users optimize energy consumption, reach net-zero targets, prevent machine downtime, and reduce costs. A high-flow model expands compressed air monitoring beyond individual machines to benefit larger air lines and systems.

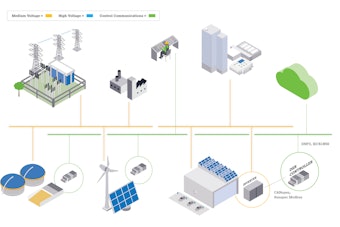

Multimedia monitoring solutions, including CoreTigo wireless communication, analyze water, compressed air, gases, electricity, steam (WAGES), and other utilities. The Edge analytics dashboard measures efficiency, optimizes productivity, and avoids or reduces downtime.

Movicon.NExT HMI/SCADA is a modular, scalable platform that solves automation problems for both CPGs and original equipment manufacturers (OEMs), from the single machine level to a complete plantwide IIoT project implementation. Among Movicon.NExT modules, Movicon Pro.Lean™ provides performance data and analytics for evaluations of overall equipment effectiveness (OEE) and Movicon Pro.Energy™ measures and tracks consumption, while the advanced Movicon NExT.AR solves operational problems through  Movicon.NExT HMI/SCADA

Movicon.NExT HMI/SCADA

PACSystems Edge Solutions is an advanced portfolio of edge computing and control systems and includes edge hardware and software that help simplify problem-solving at the machine level and allow easy, cost-effective analytics and communication at the edge. PACSystems Edge Solutions includes true edge controllers, edge computing devices, and compact controllers. They leverage Movicon.NExT, WebHMI, Connext OPC UA server, and PACEdge platforms in optimized software packages to provide powerful and flexible connectivity and visualization and a cloud-enabled toolset.

The PACSystems RSTi-EP CPE200 compact controller family delivers large programmable logic controller (PLC) capability in a compact, rugged design that allows quick and easy IIoT implementation without sacrificing performance. It provides security-by-design, open programming, and open communications, reducing cost and complexity. A range of advanced features come standard, such as OPC UA communication over high-speed 1-Gb Ethernet and C programming capabilities. In addition, it includes analytics, is IIoT-ready, and features future-proofing packaging and process systems for new technologies or existing equipment.

The Aventics Series SPRA electric rod-style linear actuator is an efficient, high-performance actuator that offers improved load capacity, accuracy, and reliability. The Series SPRA is versatile and flexible, with a choice of three different screw technologies that allow implementation in a wide variety of (demanding) applications. Compliance with the ISO-15552 standard, easy-to-use online sizing and selection tools, and a wide range of mounting accessories ensure simple selection of the appropriate linear motion solution for the application.

Aventics Advanced Valve systems form a reliable basis for both compact handling systems and complex automation solutions. The AV family offers intelligent solutions that reduce effort when creating a safe design. The valves of the AV family—AV03 and AV05—have set standards with their diagonal spool in both sizes. They are characterized by a superior volume flow ratio and energy balance. With the serial Advanced Electronic System (AES) interface, the AV valve system communicates effortlessly with modern controllers via all common fieldbus systems. The modular electronics form the basis for high networking, data transmission, and integration into Internet-of-Things concepts.

Emerson edge devices combine deterministic controllers with secure, nondeterministic controllers for analytics and machine learning algorithms to proactively optimize business outcomes. The devices are designed for remote industrial areas and equipped with Emerson vendor-agnostic PACEdge software to safely run nondeterministic applications, which reduces latency and meets all application performance requirements.

The Aventics valve system of the Series G3 electronic fieldbus platform replaces conventional, hard-wired solutions. It integrates communication interfaces with pneumatic valve systems that have input/output (I/O) capabilities. This next-generation electronic platform provides easy access to connections. It is easy to assemble, install, commission, and maintain. The functionality of the G3 enables  Aventics valve system of the Series G3 electronic fieldbus platform

Aventics valve system of the Series G3 electronic fieldbus platform

Aventics pneumatic cylinders and actuators are fundamental components of today's automated systems, regardless of how compact or demanding the application is.

The Branson GSX-E1 ultrasonic welder, and the automation systems it enables, helps manufacturers improve efficiency and reach sustainability goals. Controls automatically monitor critical weld parameters in real time, delivering actionable performance and diagnostic data to help determine OEE (overall equipment effectiveness), enable traceability, and optimize maintenance. Encryption technology ensures data integrity and security. Ultrasonic welders like the Branson GSX-E1 use less electricity, require no consumable materials, and yield less waste, cutting assembly-line carbon footprints.

Emerson and CoreTigo wireless automation solutions connect devices and unlock trapped data. The combination of expertise from Emerson and industrial wireless technology from CoreTigo results in a fully connected ecosystem that can reduce inefficiencies and help customers get to market faster. The wireless automation systems feature IO-Link Wireless, a deterministic, reliable, and scalable universal wireless communication protocol with low latency (5 milliseconds) and low synchronization rates (tens of microseconds).