This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

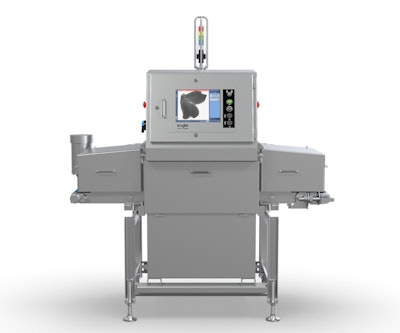

As food processors respond to growing pressure for product variety, SKU expansion, and accelerated throughput, multilane production lines have become an increasingly common strategy. The Pack 550 PRO X-ray system from Eagle Product Inspection answers this shift with a high-speed, highly flexible inspection platform designed for today’s diverse packaging formats and faster line speeds.

The need for more adaptable inspection technology has grown, with processors often reconfiguring their production lines to handle more product and packaging types simultaneously. Recognizing this shift, Eagle engineered the Pack 550 PRO to help manufacturers maintain contaminant detection accuracy, ensure product integrity, and meet evolving retailer and regulatory demands — even as packaging complexity increases.

Operating at speeds up to 90 meters per minute, the Pack 550 PRO leverages Eagle’s proprietary SimulTask™ PRO imaging software, delivering high-resolution, deep-contrast inspection even on complex product mixes such as salad blends, snack mixes, cereals, confectionery, and frozen foods. The system can also incorporate Eagle’s advanced PXT™ photon-counting dual-energy technology that enables processors to obtain much higher resolution images and capture more detailed data about the product being inspected than has previously been possible. The system allows users to differentiate materials by chemical composition improving detection in products with dense or overlapping ingredients that often challenge traditional X-ray systems.

Beyond contaminant detection, the Pack 550 PRO offers fully integrated inline quality checks, including mass measurement, package integrity verification, and component count, critical tools for maintaining both safety and customer satisfaction across increasingly diverse retail offerings.

With built-in Eagle Repository™ analytics, manufacturers can access real-time production data, rejected image archives, and comprehensive inspection records to support audits, traceability initiatives, and continuous process improvement.

“Retailer specifications, private label programs, and regulatory expectations are driving greater complexity on today’s production lines,” said Christy Draus, Head of Product Marketing at Eagle. “The Pack 550 PRO helps processors stay agile without compromising inspection performance, even when running multiple products or performing rework on the same line.”

As multilane processing becomes a standard approach to meet modern production demands, systems like the Pack 550 PRO provide processors with the versatility and data-driven quality assurance needed to future-proof their food safety programs.