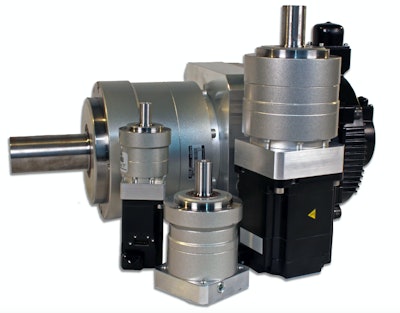

The Drives & Motion Division of Yaskawa America, Inc. released a full line of gear motors based on its Sigma-7 servo motors. The new line brings precise Yaskawa servo motion to a wider variety of automation applications than ever before, especially to uses which require high torque at low output speeds.

A new set of gearheads have been designed to pair with every servo motor in the full Sigma-7 range, creating complete gear motor solutions rated from a low of 50 watts to as high as 15 kilowatts. Five different gear ratios are available, ranging from 3/1 to 50/1.

“Using a Yaskawa gear motor gives you the best of both worlds,” says Bryan Knight, product manager for the company’s gear motor line. “You have the opportunity to match the performance characteristics of a Yaskawa servo system to a wider range of mechanical requirements than ever before. At the same time, you don’t need to sacrifice the precision and reliability that you’ve come to expect from Yaskawa.”

Yaskawa created the new line as an alternative to bolting an aftermarket gearhead onto an existing servo motor. Yaskawa gearheads are perfectly matched with their companion servo motors in mounting conventions, coupling mechanics and output characteristics. Each is custom assembled, balanced and factory tested at Yaskawa’s facility in Buffalo Grove, Ill., and includes a full Yaskawa factory warranty.

New features:

• Precision helical gearing with a 40 percent greater tooth surface area for notably smoother, quieter and more accurate operation

• An enhanced system of bearings, including 45 percent larger planet bearings for guaranteed alignment, higher stiffness, greater load capacity and longer life

• Balanced, concentric shaft couplings to minimize vibration during high speed operation and reduce the inertia of the gear motor system

• Documented performance, including 100 percent inspection of all gear motors and a report on noise level, vibration, backlash, accuracy and drive back torque

The Buffalo Grove facility maintains a complete supply of gearhead and servo motors in stock, assuring quick turnaround for assembly of any gear motor configuration in response to customer need.