The recently enacted European Union Falsified Medicines Directive (EU FMD) aims to protect consumers against falsified medicinal products by requiring all prescription medicines to be clearly labeled in a way that allows the entire production and transport process to be traced. These serial numbers are registered with a central European database and verified at the pharmacy level by scanning a data matrix code before they are given to patients.

Though the pharmaceutical industry was aware of the directive’s Feb. 9, 2019 deadline for three years, there was a frenzied increase in demand for track-and-trace systems in the months leading up to the enforcement date. Wipotec-OCS, an OEM specializing in weighing and inspection systems for processes such as printing, reading, and labeling, confirms this trend. “This is a massive drag on the market now,” says Daniel Anders, Product Manager for Track & Trace at WIPOTEC-OCS. “As of February, every company that produces prescription medication and wants to bring it on the market needs to ensure that serial numbers are assigned to the medication and that they have integrated a track-and-trace solution in their production line.”

Pharmaceutical manufacturers seek systems that can be integrated into the production line quickly and without major expenses. Another key consideration is that the systems do not slow down the production process unnecessarily, which would have a severe negative impact on production efficiency.

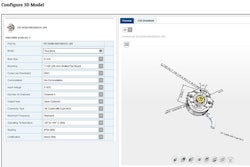

With TQS (Traceable Quality System), WIPOTEC-OCS offers modular labeling of pharmaceutical products according to all country-specific requirements. The TQS-HC-A machine combines serial numbering steps including printing, reading, labeling, and weighing into one unit. It is designed for folding cartons, which make up at least 90% of medication packaging in the European market.

The one component in the machine not fabricated by WIPOTEC-OCS is the printing unit. Whether it’s ink-jet, laser, or thermal-transfer, it comes from a third party OEM and is then integrated by WIPOTEC-OCS. Cartons are labeled on the front and/or back—optionally on the top as well—and are then weighed with a high-precision load cell to detect whether they contain the correct amounts. Faulty cartons are automatically sorted out. Where needed, tamper-evident labels can be applied to secure the packaging against manipulation.

For pharmaceutical manufacturerswho often have long production lines, it is important to have a compact track-and-trace system. With the new FMD requiring manufacturers to commit large initial investments and resources, Anders says, “We don’t want complicated systems that provide additional impediments to processes. Acceptance by the pharmaceutical industry is much higher if track-and-trace machines can fit smoothly into the overall concept.”

Ultimately, a track-and-trace machine offers the potential to simplify processes. For example, the data collected may one day make product management simpler and more convenient. “Pharmaceutical companies will become increasingly aware of these benefits once the transition required by the new directive has been completely carried out and everything has been factored in. Then it won’t just be a measure the law forces them to do, they’ll also see advantages for their own production,” notes Anders.

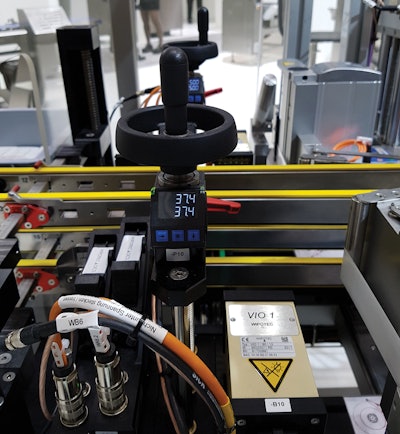

A small but significant component on the WIPOTEC-OCS machine offers advantages beyond being “non-intrusive” in the line: the AP05 position indicator from SIKO GmbH, a specialist in industrial measuring and drive technology, provides an option for supervised format changes that guides the user to the correct machine setting.

This optimized format change facilitates batch changes between various packaging sizes. In view of the ongoing trend toward smaller batches, which means more frequent format changes, this represents a significant step forward from an efficiency standpoint. All units generally need to be shifted on two axes. Up to 13 SIKO indicators may be installed in a TQS-HC-A.

These shifts must be carried out quickly, in a controlled and reliable manner. Electronic AP05 indicators are bus-compatible and can be integrated into the machine controls.

For a format change, new target values for the next folding-carton size—stored in the machine controls in a recipe list for each product—can be transmitted to the position indicator and appear in its display under the current actual value. If the actual and target values match, the integrated LED lights of the position indicator will switch to green. Otherwise, the LED will be red for “position not yet achieved.”

The machine is ready for operation again only when all LED indicators are green, and only then can production operation be started securely, preventing incorrect settings from occurring.

From the LED lights, the operator can see which shift points still need to be adjusted. This prevents defective labeling and increases process security. “What we care about is secure reproducibility of the settings,” says Anders, “to ensure that every batch and every product receives the same exact code and seal, if relevant, as the ones before. This is ensured by the AP05.”

Anders notes that changeover times are “significantly shorter and therefore more efficient” with format changes that include the AP05 indicator allowing the pharmaceutical manufacturer to focus more on critical activities such as line clearance and documentation for product quality and safety.

TQS machines from WIPOTEC-OCS were traditionally equipped with mechanical position indicators from SIKO to indicate the current position of the axes. Since WIPOTEC’s origins lie in special mechanical engineering, custom projects are par for the course. When a pharmaceutical customer requested WIPOTEC for a secure system for format changes, they collaborated with SIKO to implement the electronic indicators on the TQS-H-A.

Other WIPOTEC customers then saw the advantages of the TQS-HC-A machines equipped with electronic position indicators. The benefits—reproducibility of settings, process security to prevent defective products and damages to the machines, and reduction in changeover time—justify the higher initial investments when compared with the standard mechanical variant.

The monitored electronic variant AP05 can be retrofitted easily. Because retrofitting is possible at any time, the companies expect that more pharmaceutical manufacturers will return and upgrade to electronic position indicators once the smoke has cleared on adding traceability systems to become compliant under the EU FMD.