Efficiency in manufacturing is heavily influenced by the use of equipment. If equipment isn’t running at peak performance, then it can’t yield a large enough output to cover the initial investment. Because equipment generally interacts with both products, laborers, and conveyors that feed equipment there are multiple factors to account for when determining the effectiveness of equipment.

So how do you measure the productivity of your manufacturing equipment? How do you gain insight to improve your processes? The answer is Overall Equipment Effectiveness (OEE).

Availability X performance X quality = OEE

OEE is a standard for measuring productivity. Essentially, it identifies the percentage of manufacturing time that is actually productive. In mathematical terms, OEE = availability x performance x quality. To receive a perfect score, a machine must manufacture 100 percent availability (no stop time), 100 percent performance (as fast as possible), and 100 percent quality (only saleable products). Though a simple formula, OEE is a powerful tool that helps companies define, visualize, and ultimately eliminate equipment losses and waste. By implementing a well-designed and effective manufacturing structure, companies are able to achieve and maintain a competitive edge.

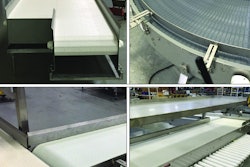

Check out Dorner Mfg. Corp's latest infographic below to learn how hygienically designed precision conveyors can help you and your company maximize your OEE.