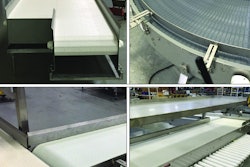

System Technology, Inc., offers maintenance-free, low cost 24 Vdc powered roller conveyors that allow multiple options for accumulating product, require fewer spare parts, accomodate plug and play controls, and use less power (71% energy saving compared to a conventional 480 volt motor system), according to the company.

1.9-in. Roller:

· Drive: 1.9-in. diameter powered rollers

· Motor: 24v DC

· Controls: Drive cards and zone photo-eyes mounted under conveyor frame

· Speed: Variable from 20 to 190 FPM

· Bed: 18-in. wide roller bed with 1.9-in. dia. x 16 gauge galvanized steel rollers spaced on 3-in. centers with 7/16-in. hex, spring loaded axles, abec-1 bearings

· Supports: Floor or ceiling supported

· Guard rail: Angle type “A” (facing inward) both sides

· Zones: Up to 36-in. zone length on a single motor

· Finish: All normally painted parts are powder painted grey. Stainless steel option available.

1.38-in. Roller:

· Drive: 1.9-in. diameter powered rollers.

· Motor: 24v DC

· Controls: Drive cards and zone photo-eyes mounted above conveyor frame

· Speed: Variable from 20 to 190 FPM

· Bed: 18-in. wide roller bed with 1.38-in. diameter x 16 gauge galvanized steel rollers spaced on 1.5-in. centers with 7/16-in. hex, spring loaded axles, abec-1 bearings

· Supports: Floor or ceiling supports

· Guard rail: Angle type “A” (facing inward) both sides

· Zones: Up to 36-in. zone length on a single motor

· Finish: All normally painted parts are powder painted grey. Stainless steel option available.

· Power supply: 480v-3ph-60hz power supplies included