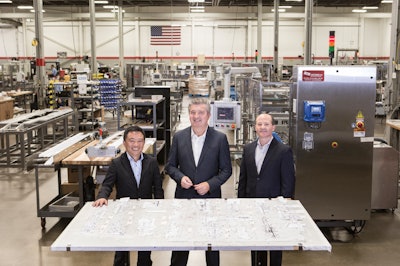

As PMI Cartoning comes up on its 25th anniversary in business, the company has much to celebrate. But, perhaps the most prominent is its recent name change as the result of a merger. As of July 1, 2018, PMI Cartoning became known as PMI Kyoto Packaging Systems, as it was acquired by Kyoto Seisakusho Co., a 70-year-old system engineering company based in Japan.

“We weren’t looking to sell, but the relationship between the two of us was a perfect fit,” says Branko Vukotic, president of the newly combined company. “Synergy is the most important part of this acquisition, especially in this kind of business where a large part of what we do is customized machinery.”

Riding this new wave of synergy, PMI Kyoto plans to add products to its existing cartoning, case packing and tray loading equipment lines that will launch the company’s presence in an untapped region, all the while, keeping its vertically-integrated manufacturing model in Chicago.

Vukotic credits the company’s reputation and the evolution of its product offering as the main factor that attracted a company like Kyoto to purchase PMI. The company opened its doors in 1993 in the Chicagoland area, selling vertical cartoners. In 1998, the OEM developed side load cartoners and in 2003 it began manufacturing case packers, dealing with side load, wraparound cases and trays.

“As we opened up and started serving different industries, we noticed an impetus for integrated systems,” Vukotic says. “So, a lot of companies either merge their business with others and incorporate other product lines, or they develop their own. As a cartoning business, almost every single carton ends up in a case or some form of corrugated shipping material, so we developed case packing and tray loading equipment, as well.” And now, with this acquisition, PMI Kyoto will focus more on system integration, systematization and expanding its services.

Two way street

While PMI wasn’t necessarily looking for a buyer, Kyoto Seisakusho has been searching for a partner since 2006. The company saw value in PMI Cartoning’s product lines, but also saw them as a conduit into the North American market. The company does roughly $300 million in sales a year, which makes it a fairly larger company than PMI, but it had difficulties finding success in the North American market on its own.

“There is a significant reason why we do not have a presence in North America,” says Ken Nagasaka, PMI Kyoto’s corporate officer, referring to the Kyoto business prior to the acquisition. “We strongly believe that the words, ‘made in U.S.’ are going to be key if we want to serve the North American market. So, we had no desire of bringing our product here, especially if it’s for the food industry, without a North American partner.”

Nagasaka says the company pondered building a factory in the U.S. to start manufacturing product, but quickly realized it wouldn’t be successful. Kyoto knew they needed to find a manufacturer that produced high-quality equipment, had a great management philosophy in place and knew how to serve U.S. customers.

As Kyoto Seisakusho leverages PMI’s North American facilities to manufacture orders it receives for U.S.-based customers, PMI will tap into Kyoto’s presence in Asia, a region PMI has had difficulty selling into.

“There is an opportunity for us to learn from Kyoto and expand in that direction of the Asian market,” Vukotic says. “Our manufacturing experiences and knowledge will be implemented into the manufacturing of Kyoto’s equipment and their business practices to improve quality. Their knowledge of the Asian market is really going to help us appeal to the Asian customer.”

Another factor that kept PMI from expanding into the Asian market—as well as other regions it hadn’t previously sold into—was that it didn’t have the capacity to simultaneously keep up with new and recurring orders while breaking into new regions.

“Our business was 80 percent repeat orders,” Vukotic says. “So, serving other markets was difficult because we reserved our manufacturing capacity for our existing customers.”

Expanding production under the same footprint

This acquisition will allow the OEM to not only expand into the region, but also allocate more resources to add engineering and production capabilities across its three Chicagoland facilities, all within two miles of each other.

The main facility, located just behind Chicago O’Hare International Airport, is home to its engineering offices, assembly floor and the new headquarters for PMI Kyoto. Next door to this main facility is the company’s machine shop, which houses a water jet and multiple machine tool centers. A third facility, just two miles away, is where the OEM rebuilds used equipment and stores spare parts and products for customer Factory Acceptance Tests (FAT).

The company has been in the Chicagoland area since it opened its doors because of the strong manufacturing and packaging industry presence just outside of the city. And Vukotic says that the company has the resources and the support of Kyoto to expand its facility if necessary, but it will also need to add talent to its workforce to adapt to growing demand, which is a challenge that every OEM in the U.S. is facing.

A murky talent pool

While the area is rich in manufacturing and packaging resources, talent is something that has been more confusing than it is a scarcity.

“We are trying to work with colleges on at least understanding what kind of talent is coming out of each school, and how that applies to our business, but it’s not always clear,” Vukotic says.

Vukotic has implemented a training program at PMI Kyoto that he feels will bridge the gap between what hired talent learned in school, or in another industry, and what they will need to know about the packaging business—and more specifically, PMI Kyoto’s business.

“Each individual we take in has to have a basic knowledge of the manufacturing industry, but we are willing to take them through the training and evaluate possibilities to employ them in the future,” Vukotic says. For example, “We train people in a couple of different areas, like in [the] electronics and mechanical [fields]. We also have a segment for welding, robotics and other areas.”

PMI Kyoto is also working with Harper College, a community college in Palatine, Ill., to recruit and train students who are nearing graduation. “The college has an interesting program where we could hire a student, and part of their training credits needed to complete the class will be done in our facility, and the other part of their training is done at Harper,” Vukotic explains.

And once new employees are hired on, they stay, Vukotic says. The company’s low turnover rate can be credited to the family-feel PMI has created within its culture. PMI Kyoto has enjoyed a long-standing workforce due to the fact that it hires family and friends of current employees. That approach helps keep the employees tight-knit and committed to the company’s overall success.

“We engage with our customers on the same level, as well,” Vukotic adds, which is why the company’s largest portion of business is from returning customers. “When we build a product for a customer, that opens up a relationship for the next 20 years because this machinery can last a lifetime. During those 20 plus years, you do become a part of each other’s lifestyle. We all call each other by first names and engage in conversations outside of business.”

Even if a prospective customer goes with a solution from a different OEM, Vukotic says PMI Kyoto maintains the relationship. And that philosophy of family-oriented business and culture allows the company to advance not just internally with its people, but externally with its customers, as well.

Finding the pain point, and filling it

Most of the equipment produced and sold is highly customized to each specific application, and according to Gary Anderson, PMI Kyoto’s director of engineering, carrying that close knit, family-feel approach over to the business side of things helps them in the highly customized arena.

“It goes beyond just the equipment, but really looking out for our customers’ best interests and [keeping] functionality in mind,” he says. “Through our experience, we’re able to ask the correct questions as far as the performance requirements for a given machine. And then tailor the design and optimize the design for the particular requirements. That’s something that is garnered through this relationship that we have with our customers and knowing their process precisely.”

PMI Kyoto has a standard offering of machines, but almost every single order is modified and optimized for a particular customer’s product type, rate and production environment. And PMI Kyoto also has a hand in customizing the packaging materials and cartons for the equipment.

“We get so involved with customers beyond the equipment itself,” Vukotic says. “We advise and select the best possible packaging materials and designs for our customers so that we can build in and notice efficiencies. For example, a simple change to the carton size, style or closing design can save customers money by lowering the cost of materials and the amount of glue needed to close and seal the cartons.”

Since the OEM also manufacturers case packers and tray loaders, they have had to accommodate many different packaging formats that their customers wish to use, like stand up pouch bags, jars and bottles, which has opened up additional business segments, industries and opportunities for PMI.

Keeping a close eye on new markets, trends

One of the industries PMI Kyoto has been selling into for almost 10 years now is pharma. Similar to the food industry, pharma has its share of strict regulations—like serialization compliance—that require OEMs to develop equipment with close attention to the fine print.

“From the standpoint of our equipment, there’s not really much we need to do when it comes to serialization, but what our equipment puts out needs to match the requirements that are given by the FDA,” Nagasaka notes.

PMI Kyoto has serialization covered on the pharma side, but the team is closely watching as the FDA requirement makes its way into the food industry. “This is going to hit, and it’s going to hit big time,” Nagasaka says. But PMI Kyoto says it is ready.

In addition to that, PMI Kyoto will also be looking to break into the liquid packaging market.

“The main motivation and drive behind us getting into liquids is the fact that we have designed these tray loaders, wraparound sleevers and cartoners. This equipment is ready for products in jars and bottles, like energy drinks and pharmaceutical liquids,” Vukotic says.

Ramping up for the future

While keeping their finger on the pulse of emerging trends that could propel them into new markets, PMI Kyoto has been increasing its level of production due to the acquisition, causing it to implement lean practices and other methods to ensure the plant floor is churning out equipment and keeping up with its 12 to 24 week lead times.

Because the OEM is vertically integrated, all parts and processes are done in house. In the absence of an enterprise resource planning (ERP) system, PMI Kyoto is trying a new approach to lean and project management to keep everything on schedule. The OEM has its people on the shop floor monitor every process, and how long it takes for each process to be completed.

“Let’s say you have a CNC process that should be completed in 20 minutes. We want to encourage our people to be creative and see if they can do it in 15 minutes,” Anderson says. “This is how we’re trying to motivate them to eliminate any bottlenecks. If they can shave off five minutes anywhere, that will boost our productivity, and they will get credit for that.”

Anderson says the company tried to implement a system like this 20 years ago, but it came across as micromanagement to the employees, which lowered morale and productivity. But PMI Kyoto reworked the initiative and has built in a reward system to boost morale and help its people succeed in their roles.

“The program is just getting started, but it’s being accepted very well on the floor because everybody feels confident being able to look back at what they did for the day and see that they saved time or completed a project,” Anderson says. “Once the program is accepted and fully up and running, we will raise the bar gradually so that people can see how the company adapts to this growth.”

PMI Kyoto has been growing over time to accommodate the influx of orders and new equipment lines it will manufacture in house since Kyoto initiated the acquisition in December of 2017. The company is currently augmenting the existing PMI product line and technology with developments that Kyoto has had, which the OEM can now include in the PMI offerings.

Catch PMI Kyoto at PACK EXPO

Increased production isn’t the only thing PMI Kyoto is preparing for, as they are planning the debut of a cartoning machine that has a throughput of 1,000 cartons per minute at PACK EXPO International, held in Chicago Oct. 14–17. According to Vukotic, the cartoner is one of a kind, and one of the fastest in the world. See them in booth