This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

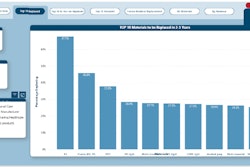

The platform enables users to collect, manage, and analyze data from hundreds of factory devices, including ABB robots, to determine key performance indicators including cycle time and overall equipment efficiency (OEE). By speeding up diagnostics and decision making, OptiFact increases the production line uptime with less engineering effort, ensuring production can keep pace with customer demand.

OptiFact adds to ABB’s comprehensive suite of leading digital solutions that help businesses of all sizes imagine new digitally enabled processes, realize them on the factory floor, and elevate operations by simplifying production to increase productivity and flexibility. With OptiFact, factory operators can determine the root cause of production errors and use ABB’s RobotStudio® Cloud to make adjustments to the program and develop an improved robotic solution.

OptiFact has been deployed in several production facilities, including a highly automated automotive production environment, where it collects and analyzes production process cycle times and other key performance indicators, providing unparalleled visibility into factory operations and saving up to 25% of experts’ time. As a result, the customer has added the deployment of over 580 robots in its operations.

The platform has also proven its value for small and mid-sized enterprises. An additional pilot demonstrated the platform’s ability to identify production bottlenecks in production lines involving up to 20 robots. The customer’s digital team integrated OptiFact into its production environment in just two months from first contact to final delivery. Once deployed, OptiFact simplified data collection and the visualization of key performance indicators such as cycle time and Programmable Logic Controller (PLC) alarms. By addressing operational inefficiencies detected using OptiFact, the facility increased production time by up to 20%.

ABB is holding a public preview competition, in which 20 winners will receive free access to OptiFact for six months, including access to customer support to test the platform, collect data, monitor equipment, and improve production efficiency.