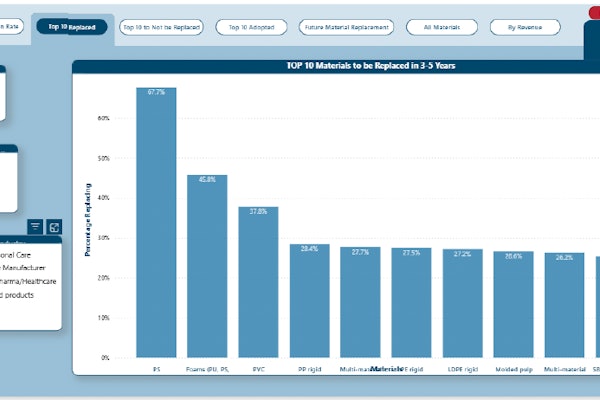

Pre-pandemic, rapidly expanding SKUs was a prominent trend in the CPG industry, created by customized products, a broadening of product shapes and sizes, and growing packaging material options for single products.

Some of that expansion slowed (in certain markets) during the height of the pandemic due to supply chain disruptions and the need to focus on the most popular SKUs. It is expected, however, that SKU counts will continue to grow in the coming year.

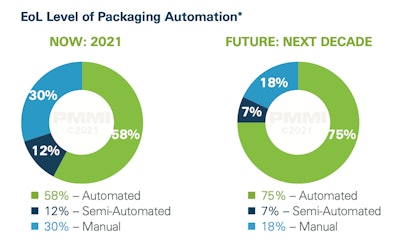

SKU growth means more challenges and requirements for manufacturers, and flexibility is a key necessity for EOL machinery to accommodate new strains on production. The integration of several different functions into one machine is streamlining production and expanding automation in the EOL space. Machine flexibility is also crucial for contract manufacturers and packagers, driven in part by the added production strain placed on manufacturers.

The ability to adapt to a wide variety of packaging shapes, sizes and materials has become extremely important. Labeling machines, especially direct-print systems, must handle a wide variety of shapes and material types. Handling equipment must be capable of adapting to diverse packaging formats, including products packaged in PCR material that can vary in quality. Even wrapping and banding equipment must be highly flexible, capable of adjusting to an array of secondary packaging shapes and pallet configurations. In some instances, EOL machines must also utilize print registered films to bundle products for movement through the supply chain.

One method of obtaining greater levels of flexibility is the integration of robots and cobots in the EOL space, particularly in palletizing. Robotic palletizers are ideal for consistently constructing stable pallet stacks that maximize space efficiency, allowing manufacturers to adapt to a variety of packaging formats, from flexible to rigid. Stacks constructed by robots can also more easily be arranged to retailers’ specifications, enabling them to drop configured pallets directly onto the shopping floor. With integration and advanced HMI configurations, alterations to pallet construction can be changed on the fly, allowing EOL operations to seamlessly transfer from one product to the next by adjusting stack formations to the desired dimensions and configurations. Three out of four large and medium-sized manufacturers are using robotics at EOL now, with several predicting 100% robotic palletizers in the future.