In just five years, Pressed Juicery has grown from a broom closet in Los Angeles to nearly 30 stores with national distribution and a presence in Costco. Created by three childhood friends with the goal of making nutrition a realistic option for everyone, customers claim the juice products not only taste good, but make them feel better when they drink it. Made from 100 percent fruits and vegetables, the juice is coldpressed using a custom hydraulic press to gently extract the maximum vitamins and minerals from fresh produce. Jill Costelow, Pressed Juicery’s vice president of operations and supply chain, tells us about the uncommon relationship her team has with its OEM suppliers.

PP-OEM: Pressed Juicery is a unique company with a unique product. What are your unique packaging and processing needs and solutions?

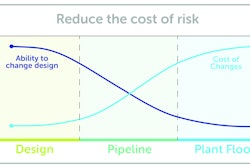

Costelow: We are in a fairly new market that’s starting to emerge, and the consumer base is driving change very quickly. Most of my capital projects have two- to six-month timelines. They are not one-year or three-year projects because our consumer base can be onto a completely different style of products by then. We start with fresh fruits, vegetables, and nuts and make those into juices. There are no additives, no preservatives, and no water added to the juice products. It is what is on the label. So, it’s a challenging type of product to make because you are dealing with whatever is available from the fresh produce industry. Other juice companies may be able to take advantage of either frozen concentrates or frozen juices that they can store long term. We are dealing with fresh produce that is coming out of the farming industry on a daily basis.

From there we use a centralized manufacturing facility that makes all the products via cold-pressed processing or highpressure processing. We are taking advantage of some of the technologies for the super premium market that are out there.

PP-OEM: Do you have to eliminate certain companies right off the bat if they aren’t going to meet the standards that you need?

Yes. When Pressed Juicery first started, it used the industry standard for the cold-pressed process. As the business grew, some of the technologies didn’t meet our needs for a lot of different reasons. We partnered with several companies that may not have used their equipment in the juice industry before to come up with a proprietary and patented process. We approached them and said, ‘We have this concept; here is what we want to do with your equipment. What are your thoughts on that? Do you think it’s a viable process and would you partner with us to develop that type of equipment for what we are trying to do with it?’ We were looking at not just traditional equipment in the juice industry, but what’s out there in food and non-foods industries.

PP-OEM: Were you forced to do this to meet Pressed Juicery’s standards or was this something that evolved from seeing machinery in other industries?

We have a fairly senior team with a lot of experience and knowledge. We also have several people connected with PMMI’s OpX Leadership Network. This leaves us with a lot of connections in the industry. Our Freeze Product is a new release that I can use as an example of our approach. Our owners and our director came to us with a frozen fruit and vegetable juice concept and said, ‘We want to make this product.’ We will take the concept to the equipment manufacturers that traditionally make that style of equipment, and we will say, ‘We want to make this product with this equipment. What are your thoughts?’ They usually will come back with, ‘No, our equipment won’t be able to do that,’ or ‘Yes, maybe there is something we can do to meet your needs.’

In this particular case, we went to the traditional equipment in the food environment and found that nobody could meet our expectations. So we looked outside the food or juice industry to see what else was out there that people use to mix product. For Freeze, we looked at machines used by asphalt companies that were grinding up rocks and asphalt to create a granular mix. Could we apply that concept in a food grade stainless steel environment? In the end, we left ourselves with a wide range of opportunities.

PP-OEM: You have a company-wide collaborative approach where everyone agrees that the solutions may cost more than traditional machinery. Are there ever issues with getting machinery designs through procurement?

Yes, we have budgets that I have to meet so I would say that we have the same challenges as any company. What we do is we keep pushing the envelope and working with different companies to find who has a concept that will work within all the parameters that we need to meet. We find out the right connections.

PP-OEM: Do you have established suppliers now?

We have established some key partners that work with us. For us, it’s not really about an OEM being large or small. It’s about who has the right philosophy and is willing to partner with a company like us that is quick and nimble. The smaller equipment manufacturers have emerged as the ones willing to tinker around with our ideas. They like doing R&D stuff. On the flip side, we bring value to these equipment manufacturers by letting them come in and play around with other concepts. We serve as an R&D lab for them in a true manufacturing environment. It’s a good partnership.

We actually took one piece of equipment, put it into manufacturing here, and within two or three months, it was beaten up. As we began fixing and upgrading the components, we told the OEM, ‘We are going to upgrade such and such component, here is our recommendation. What do you think?’ As we upgrade, we are helping them redesign, maybe, a heavier duty model that can handle all of our manufacturing down the line. Now, they have a robust piece to market that’s a little more expensive but we have done all of that design work for them. We are pretty open to sharing with our equipment suppliers.

PP-OEM: Are there any pain points or issues that you have with OEMs?

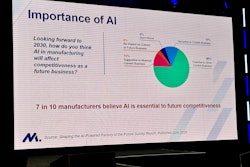

The consumer products groups have to deal with their consumers wanting new products every few months. Then the industry has to figure out a way to stay in touch with that and drag along the equipment manufacturers and suppliers. Those equipment suppliers that are really embracing it and trying to figure out how to adapt more quickly are the ones that are going to prosper going forward. Consumers aren’t going to stop. They are going to keep demanding changes whether it’s in packaging design or processing of new products. The entire industry, the CPG side and the equipment side, is going to start to embrace flexibility because it is not going to stop.

PP-OEM: As your machinery needs change with new products, are you able to adapt or upgrade equipment without wholesale capital investments?

Here’s a good example of a project that we just kicked off. Our owners wanted to launch a 2-oz. shot product. Since we weren’t quite sure if it was going to be a hit with our customer base, we test launched it in several of our stores. In the four-week test, it did well. The owners of the company came back and asked when can we launch it across all the stores. So, we started looking at the volumes that we needed to produce and realized that the equipment we had couldn’t run the volumes needed to launch it across the entire customer base. How can we get production ramped up? When you think about it, if I need to put in an entirely new bottle line, it would virtually be impossible to do something within a month or two months. So, we have to look at what’s out there on the used market that we can get our hands on now to get the line up and running. We were able to find a not-so-brand-new line that was never installed, so we were able to purchase that. Then the next phase becomes, ‘How quickly can we get change parts? How quickly can we get this line retrofitted to run the product we need?’ The ones that we partnered with were equipment manufacturers who were very receptive, and we should be able to pull it off within about three to four weeks. The line has the proper change parts for our just-launched shot bottles. We were able to pull that project off within six weeks from our first conversation.