Additive manufacturing systems are quickly evolving from a tool primarily for prototypes to a mainstay of volume production. In the complex world of advanced packaging equipment, 3D printing is helping companies trim costs and shorten development time. The benefits are so distinct that early adopters still recall their transformational first experiences with the technology.

“The first part we did was a part for applying a label. The customer found that too much wind caused a label issue,” says Rick Fox III, manager of machining services at Fox IV of Export, Pa. “They sent their machine, and I designed a part that would have been difficult to machine because it had thin, curved pieces. I got it ready to go in an afternoon instead of waiting two or three weeks to get a machined part that may not have worked.”

At Axon Corp., Raleigh, N.C., the first use of the additive system may have cemented a business relationship. Foreign visitors were checking some equipment when engineers found that a part had broken. Being able to solve the problem quickly prevented what could have been a difficult decision for the visitors, who would have had to decide whether to stay longer, fly back later or quash the deal.

“The first time we used the 3D printer, we had 12 people here from Taiwan,” says Ken Nyren, director of engineering at Axon. “The machine needed a custom bearing to support a part. Normally, it would take two days to a week to get it, which would have been a major problem for them. They went to lunch, and by the time they came back I had designed and printed the part. It’s hard to put a value on that.”

A growing number of packaging companies are deciding that additive manufacturing equipment is highly valuable. 3D printers are quickly being transformed from a tool for developing prototypes to manufacturing equipment for production runs.

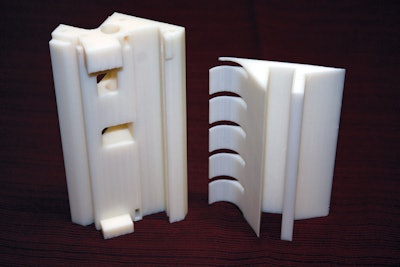

“We have designed lightweight complicated vacuum chambers and grippers for end of arm tooling on robotic systems,” says Erik Kwiatek, mechanical design engineer at Schneider Packaging Equipment, Brewerton, N.Y. “We prefer to create finished parts ready for production, so we skip the prototype stage some companies go through.

In the early years of 3D manufacturing, materials weren’t reliable enough to meet the demands of many industrial applications. That’s changed significantly in recent years as both material suppliers and equipment makers continue making improvements.

“We ran the 3D parts through 1 million test cycles before we decided that they really worked,” Fox says. “There’s no wear and tear difference from any other production parts.”

Companies that routinely use additive manufacturing note that the technology has altered their strategic plans. The ability to design very customized products helps them meet customer demands with precise solutions that can often be delivered on very tight timeframes.

“This allows us to position ourselves as a partner, not a vendor,” says Bob Williams, sales and marketing vice president at Axon Corp. “We can help the customer get the best solution from a cost standpoint and time to delivery.”

Also, material costs can be lower when there’s no expensive material being milled away. There’s a certain inherent efficiency in using all the material you buy. Plus, nonrecurring engineering costs can also be trimmed when multiple prototypes can be created in less time than it takes to get one version machined.

“A part that used to cost $20 for a supplier to make now costs $6,” Fox says. “It takes around two hours to do a whole group instead of waiting roughly a week to get two or three parts from an outside supplier. That’s not to mention that we can set the printer to automatically turn off so we can make parts overnight.”

Users also note that they can now make parts with complex shapes and sizes that weren’t practical, previously. Additive processes also make it simple to use multiple materials. Nyren notes that some of the parts Axon makes “are impossible to do without the printer.”

That’s forcing product designers to alter their thinking. Solutions no longer have to account for the challenges imposed by conventional manufacturing processes. Components simply have to meet the usage requirements.

“With 3D printing there are no constraints of how you design a part,” Fox says. “Our engineers still think about how they can machine a part instead of thinking about what they need and printing it.”

While more and more parts are being made using additive methods, longstanding manufacturing processes aren’t universally seeing noticeable declines. And though they are now used in production, additive machines still have a foot solidly in the prototyping camp. Often, prototypes are created using 3D printers, then production runs are milled.

“The amount of machining we do hasn’t gone down,” Nyren says. “It’s not uncommon for us to develop parts and send them out to be machined. The difference is that we can used to send out our prototype design and wait two weeks, and everyone knows the first version never works. Now we print one, make changes until it works, then send that design out.”

Sometimes, that decision is made because many materials can’t yet be processed using additive manufacturing techniques. Other times, the cost of conventional materials and processing is below that of additive techniques.

“3D aluminum sintered and stainless steel technologies already exist,” Kwiatek says. “These are a great fit, but the cost is so high it is hard to justify, so we end up designing a CNC milled part instead.”

However, material advances are giving users of 3D printers more options. Wohlers Associates, an independent consulting firm, says 3D printing is a $4 billion market growing at more than 30 percent per year. That’s prompting materials companies to invest heavily, expanding market offerings. Over the past five years, materials have become more water resistant and more chemical resistant. Printable materials more closely mimic nylons, thermoform plastics and other materials. They match the performance of production material.

“The biggest mistake I made was spending a couple years researching to get the target machine for what we needed,” Nyren says. “If I’d gotten something close early on, it would have paid for itself in two months. I’d definitely advise someone to buy something now and start benefiting from it.”