This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

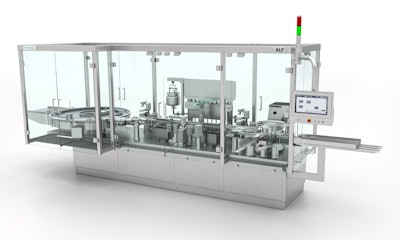

Syntegon's Settle Plate Changer (SPC) for automated viable monitoring in the aseptic filling process is a patented robotic solution that will support customers in complying with the latest Annex 1 for new and existing equipment.

Higher machine availability thanks to automation

“Environmental monitoring is essential in aseptic manufacturing and has become even more important in the context of EU GMP Annex 1,” says Steffen Gröber, Global Product Manager Service at Syntegon.

Settle plates may be exposed to cleanroom air for a maximum of 4 hours and must then be replaced to ensure consistent sampling for liquid filling operations. With the new robotic handling unit from Syntegon, this step now can be performed automatically, significantly reducing the previously required production interruptions.

“Thanks to the SPC, machines only need to be stopped once a day for viable monitoring, which results in noticeably higher machine availability of up to 300 hours per year and therefore more sustainable processes,” says Gröber. Process reliability and traceability also can be increased thanks to optional barcode scanning.

The new Settle Plate Changer SPC from Syntegon automates viable monitoring and reduces production interruptions and human intervention in the process zone to a minimum.

The new Settle Plate Changer SPC from Syntegon automates viable monitoring and reduces production interruptions and human intervention in the process zone to a minimum.

Reducing manual intervention and contamination risks

In addition to significant advantages for productivity, the Settle Plate Changer fulfills another important Annex 1 requirement: reducing manual operator intervention in the process zone for environmental monitoring by 80% and thereby minimizing the risk of contamination to a minimum. In the second chapter of Annex 1, automation and robotic systems are particularly emphasized under the keyword “appropriate technologies” for maintaining sterility.

“The SPC reflects our commitment to meeting regulatory requirements at all times and to always putting customer needs first. Even before Annex 1 came into force, we started developing our automated solution and secured the patent,” says Muhammed Ali Turac, Project Manager Automation at Syntegon Service.

Seamless and sustainable integration in new and existing machines

The Settle Plate Changer from Syntegon is available both with the purchase of a new machine and as a retrofit for existing equipment.

“What's more, it can also be seamlessly integrated into all machines and control systems from third-party suppliers,” Steffen Gröber emphasizes. “As a result, we ensure that the service life of existing equipment is increased and pharmaceutical manufacturers can run more sustainable processes thanks to reduced downtimes.”

Syntegon will present the new SPC in Booth 18099 at PACK EXPO International 2024, November 3-6 in Chicago.