In general, the adaptation of digital protocols like EtherNet/IP or Profinet has made it easier to use and access multivariable measurements, according to Ola Wesstrom, senior industry manager of food and beverage for Endress+Hauser. With these protocols, just one set of wires provides measurement information along with very advanced diagnostic capabilities.

It also provides the added possibility of doing verification on instruments, he adds. “It brings up the overall trust of measurements,” he says, pointing to the very real possibility that instruments could start to drift a couple weeks after annual calibration. Onboard verification of instruments provides reassurance that the measurement is correct. “Very fast implementation of EtherNet/IP in the food industry has really opened up this possibility.”

>>Read more about the latest sensor innovations in the food and beverage industry in "New Technologies Feed the Hunger for Information."

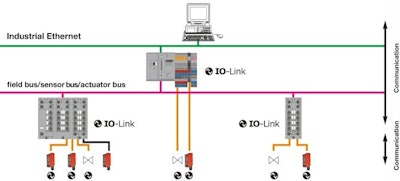

Several sensor suppliers pointed in particular to the increasing prevalence of the communication protocol IO-Link and what that has meant for industry, providing instant information on product status as well as the health of the sensor. “Data can include runtime data, temperature information, and time series output data, which can all be used to improve productivity by showing trends in machine failure as it relates to reduced sensor functionality, damage, or failure,” says Michael B. Hamoy, product manager for sensors at Omron Automation America.

Through the IO-Link Consortium, suppliers have come together to agree on providing the same information. So, in theory, any vendor’s IO-Link sensor can go onto any IO-Link system. From a technology perspective, IO-Link provides simplified installation, automated parameter settings, and expanded diagnostics.

A key benefit that Christ Makris, director of production management and marketing for Baumer, points to is the ability to use parameter data storage and duplication to easily switch out a sensor with a new one. “You can just take another sensor off the shelf, not have to program it at all, plug it into that system, and because it’s plugged into point A, IO-Link knows at point A, this sensor should be configured this way and it automatically configures it,” he says.

Though IO-Link has been around for several years, it’s really gaining traction now. Baumer has had IO-Link capabilities in a number of its sensors for at least 10 years, but only now is the awareness and request for it from customers on the rise. “With IO-Link, you actually can get more detailed data of the sensor and reconfigure it and even change the sensor because you have all the capabilities coming back,” Makris says. “You’re able to pull more capability out of that sensor and configure it and fine-tune it better.”

An overwhelming majority of change going on with sensors comes from the digital information provided by standards like IO-Link, according to Greg Kline, food and beverage industry manager for Vega Americas. “IO-Link is going to be more rapidly adopted, in my opinion,” he says. “It has the ability to get continuous data digitally back to the control system. That’s what I see as the advantage.” Vega has included IO-Link in its new compact Vegabar and Vegapoint series instruments.

It’s part of a general trend toward more intelligent sensors, notes Andreas Eberle, key account manager for food and beverage at Leuze. “More sensors are interfacing with the machine, sending data up to machine control via bus systems like IO-Link or ASi bus,” he says. “This is getting more and more interaction with the machine.”