Thanks to robust sales, the Londonderry, NH-based organic yogurt maker is now making changes to both its packaging machinery and materials to meet increased demand.

"We needed additional capacity," explains John Daigle, vice president of operations for Stonyfield Farm. "Our cup filling equipment was only four years old, but its capacity was 25ꯠ cups per hour. To get to 35ꯠ an hour we would have had to put in another line and added three more operators. And then we would have still had to run those individually filled cups through cartoning equipment." Outsourcing the work to a contract packager, he says, would have been cost prohibitive.

A more attractive option, Daigle says, was to add an in-line thermoform/fill/seal machine that its Paris, France-based parent company Danone had used. "Danone had several of these machines and they liked them a lot." So Stonyfield removed the cup filling line and began production in April on a new Model 6D-24 tf/f/s unit from Arcil.

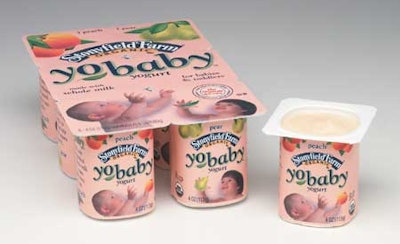

"Its capacity is 40ꯠ cups per hour," says Daigle of the tf/f/s unit. A critical difference with this equipment is that it forms 24 cups at a time, and fills and lids them before a knife system cuts them into four six-packs." After cutting, the six-packs are discharged from the machine and are conveyed to downstream case packing.

The 0.41"-thick polystyrene sheet is supplied by Witt Plastics. Alcan supplies the lidstock. From the outside-in, this material includes overlacquer/six-color gravure printing/clay-coated paper/adhesive/metallized polyester/heat sealant. Specific thickness details were unavailable.

Asked how the material switch fits into Stonyfield’s pro-environmental stance, Daigle replies, "We’re evaluating different polymers, but right now they don’t exist for thermoforming on this equipment. What we’re really looking at is a 37-percent reduction in the weight of raw materials because we’ve eliminated the paperboard wrap. The thermoform/fill/seal equipment is our most economical way to address our capacity issues."

YoBaby retails nationwide for $3.19, and is available in three different varieties, each including two different flavors. Sold refrigerated with the same 50-day shelf life as the previous materials, the new packaging is said to take up less shelf space and provide retailers with improved product merchandising opportunities.