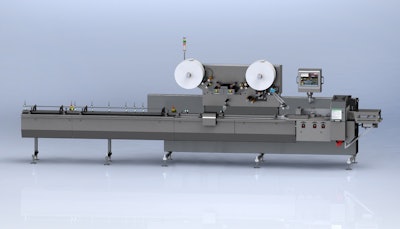

Campbell Wrapper’s new Revolution HS flow wrapper features Allen-Bradley servo drive technology with 5700 Kinetix drives and VPF servo motors, a PanelView Plus 7 1500 touchscreen, an easy-clean sanitary design, and quick changeover, and is capable of running both cold seal and heat seal films at speeds to 1,200 packages/min. The wrapper offers servo-driven film roll spindles, feed rolls, independently driven fin wheel assemblies, and a fin turner and cutting head for accurate cutoff adjustment. According to the company, the wrapper features state-of-the-art film tension control, film splicing with enhanced ergonomics, automatic web tracking, and a sanitary modular design.

![What we expect in coming years, and actually, towards the second half of this year, is that the demand [for growth] will be driven by trying to address [ongoing] workforce challenges.](https://img.oemmagazine.org/files/base/pmmi/all/image/2022/10/What_we_expect_in_coming_years__and_actually__towards_the_second_half_of_this_year__is_that_the_demand__for_growth__will_be_driven_by_trying_to_address__ongoing__workforce_challenges..63486df187c93.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=167&q=70&w=250)