Manufacturers are beginning to embrace agentic AI to reshape operations across the back office, production floor, and customer-facing functions, according to Deloitte’s new latest report, “From Vision to Value: A Roadmap for Enterprise Transformation in Manufacturing with Agentic AI,” Deloitte research shows that 26% of companies are already exploring agentic AI at significant levels, signaling early but meaningful momentum.

The real power of agentic AI lies in enabling transformative outcomes—bridging gaps between disparate systems and unlocking efficiencies often lost in handoffs. For example, AI agents can autonomously reconfigure production lines in response to disruptions such as part shortages or equipment failures, offering a glimpse into a more adaptive, resilient manufacturing future.

A data-driven approach is key to realizing the technology’s full value—identifying high-impact opportunities, reducing employee pain points, and boosting worker productivity. At the same time, Deloitte’s analysis of 12.3 billion industrial manufacturing task hours underscores that human expertise remains central, with 81% or more of tasks expected to stay human-driven.

The following are six key takeaways from Deloitte’s Agentic AI in the Manufacturing Industry report:

1. From pilots to scale: Agentic AI isn’t just another automation tool—it’s about AI agents that can act independently, make decisions, and collaborate across systems. Manufacturers are encouraged to shift from small pilots to scalable road maps that deliver measurable ROI at the enterprise level.

2. Broad business impact: Agentic AI can deliver value across the entire operation—from engineering and the shop floor to supply chain, sales, and aftermarket services. For OEMs, this could mean faster product development cycles, more resilient production schedules, and expanded service revenues.

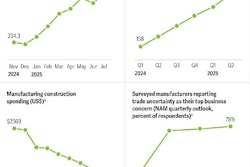

3. Supply chain resilience: AI agents can proactively monitor global conditions (weather, logistics, tariffs) and autonomously reconfigure sourcing or production schedules to minimize disruption. This agility is crucial in today’s volatile trade and labor environment.

4. Smarter design and production: In product development, agentic AI can crunch customer data, iterate design options, and generate manufacturing instructions automatically. On the line, it can adjust workflows or machine usage in real time to maximize uptime.

5. Aftermarket opportunities: With aftermarket services already providing double the margin of equipment sales, agentic AI can elevate customer support through virtual assistants that guide repairs, order parts, or schedule service calls—helping OEMs build loyalty and generate new revenue streams.

6. People + AI, not people vs. AI: Despite automation, Deloitte estimates over 80% of manufacturing task hours will remain human-driven. The real opportunity lies in combining agentic AI with human judgment, supported by reskilling and change management to prepare the workforce for new roles and decision-making dynamics.